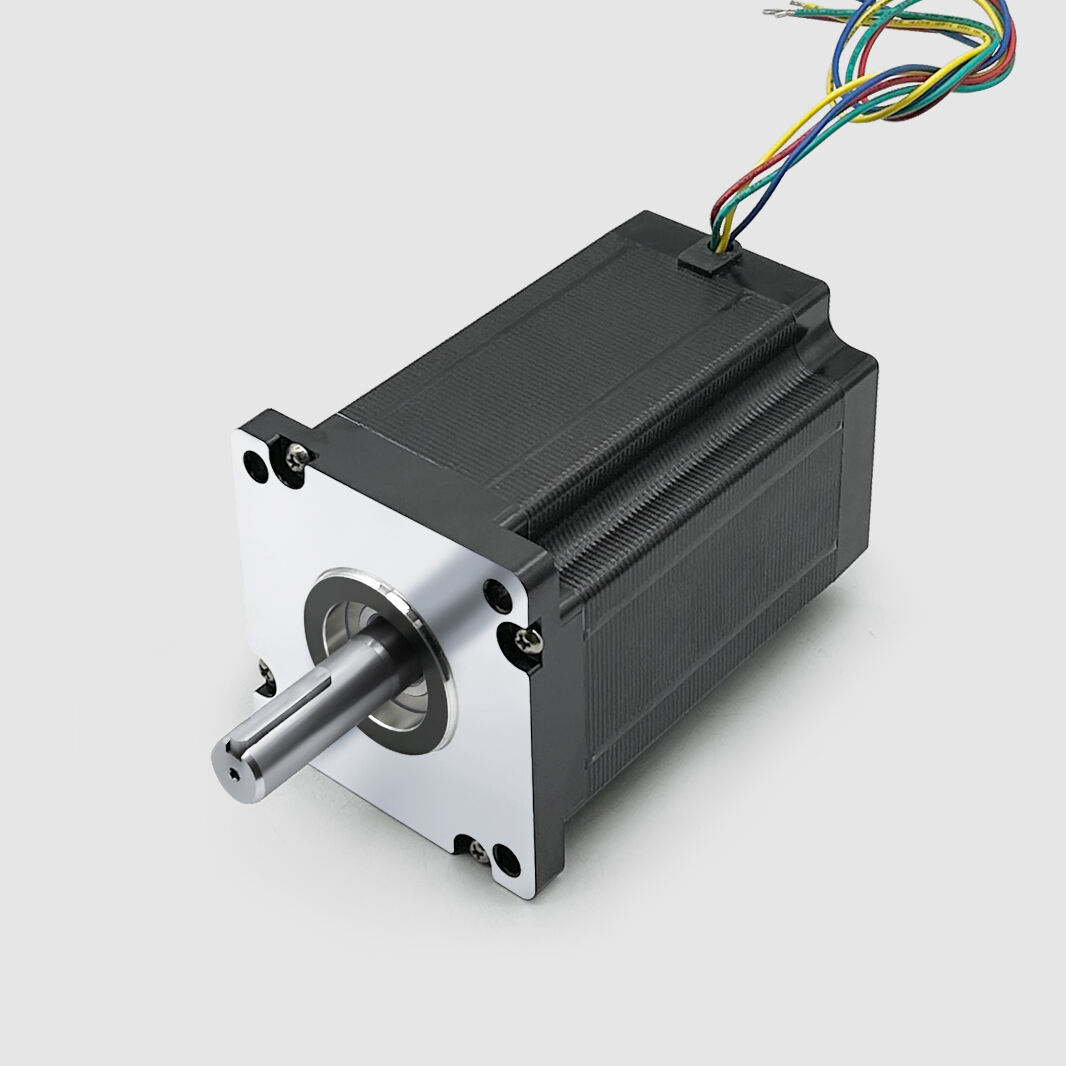

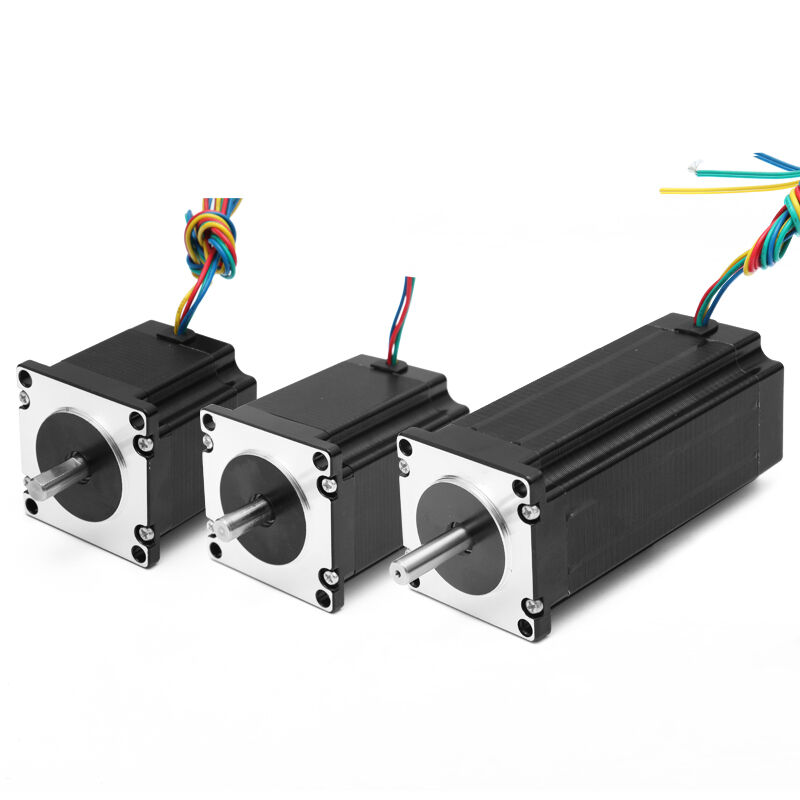

nema 17 closed loop stepper motor

The nema 17 closed loop stepper motor represents a significant advancement in precision motion control technology, combining the reliability of traditional stepper motors with sophisticated feedback systems. This motor follows the NEMA 17 standard, featuring a 1.7-inch square faceplate that ensures universal mounting compatibility across various industrial and commercial applications. The closed loop configuration sets this motor apart from conventional open loop stepper motors by incorporating an encoder or sensor system that continuously monitors the actual rotor position and compares it with the commanded position. This feedback mechanism enables real-time error correction and significantly improves positioning accuracy. The nema 17 closed loop stepper motor operates through a sophisticated control system that processes feedback signals and automatically adjusts current levels to maintain precise positioning. The motor's technological features include high-resolution encoders, typically ranging from 1000 to 4096 pulses per revolution, which provide exceptional position feedback accuracy. Advanced driver electronics process this feedback information within microseconds, ensuring rapid response to any position deviations. The motor maintains the traditional stepper motor's ability to hold position when stationary while adding dynamic performance improvements through closed loop control. Applications for the nema 17 closed loop stepper motor span numerous industries, including 3D printing, CNC machining, robotics, automated manufacturing, packaging equipment, and medical devices. In 3D printing applications, these motors deliver superior layer accuracy and reduced vibration, resulting in higher quality prints. CNC applications benefit from enhanced cutting precision and reduced step loss during high-speed operations. Robotics implementations leverage the motor's precise positioning capabilities for accurate joint control and path following. The manufacturing sector utilizes these motors in pick-and-place systems, conveyor controls, and assembly line automation where positioning accuracy directly impacts product quality and production efficiency.