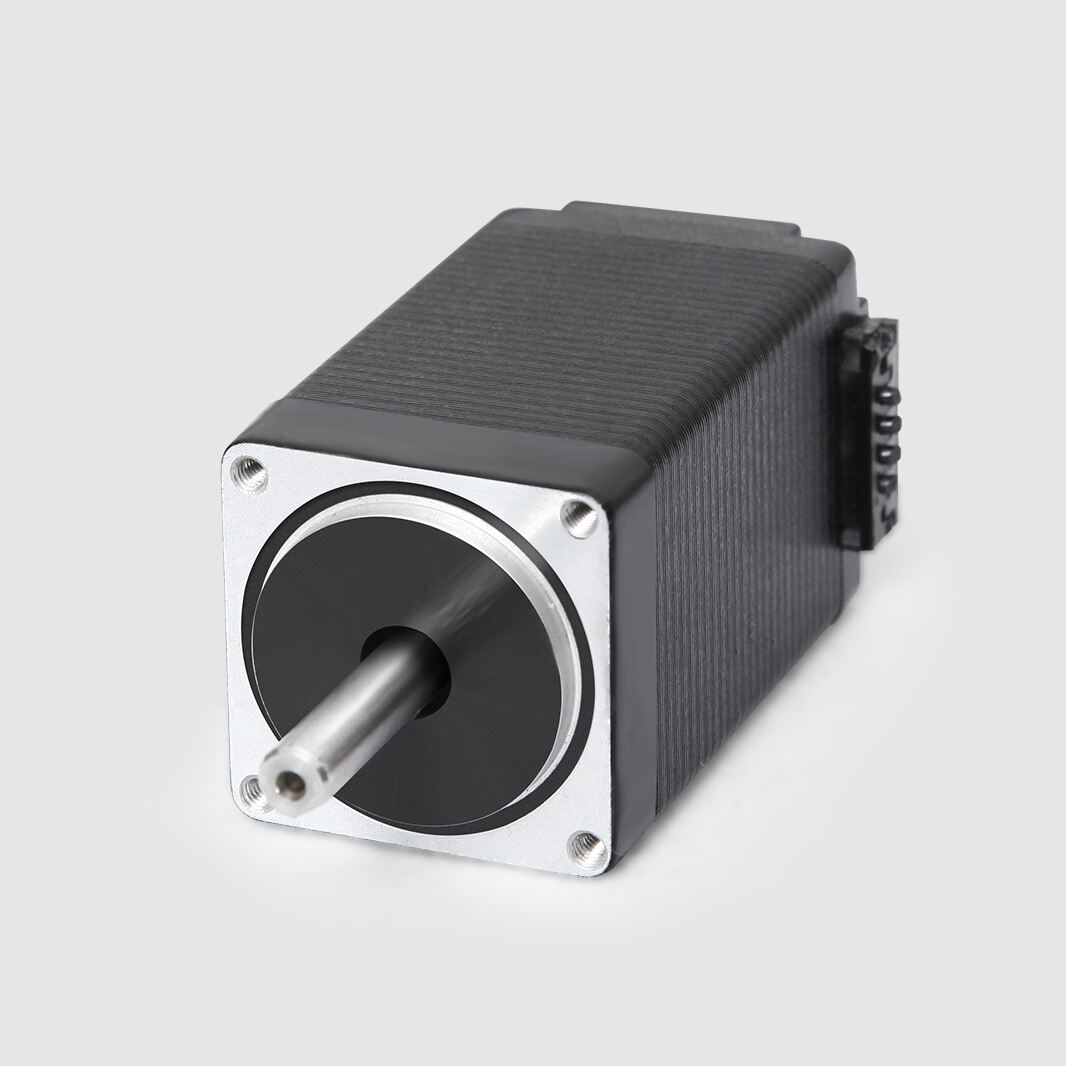

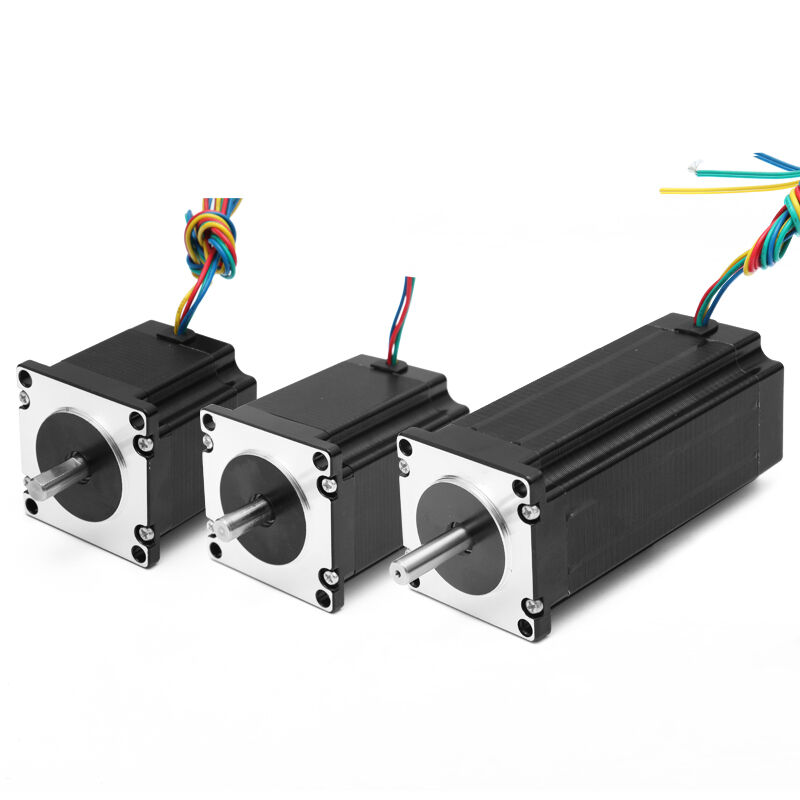

Versatile Integration and Cost-Effective Implementation

The NEMA 24 motor demonstrates exceptional versatility in integration scenarios, offering plug-and-play compatibility with diverse control systems, mechanical interfaces, and application requirements that significantly reduce implementation costs and development timelines. The standardized mounting configuration adhering to NEMA specifications ensures universal compatibility with existing machine frameworks, eliminating the need for custom mechanical adaptations when upgrading or replacing motor systems. This standardization benefit extends to electrical connections, as NEMA 24 motor wiring configurations follow established industry conventions that simplify installation procedures and reduce the likelihood of connection errors during setup or maintenance activities. The motor's compatibility with multiple driver technologies, including basic step-and-direction interfaces, advanced microstepping controllers, and integrated motion control systems, provides flexibility in selecting cost-appropriate control solutions based on specific application requirements. Cost-effectiveness emerges from the NEMA 24 motor's ability to eliminate expensive components typically required in alternative motor technologies, such as optical encoders, resolver systems, complex feedback controllers, and precision gear reducers that add substantial costs to motion control implementations. The open-loop operation capability of the NEMA 24 motor reduces system complexity by eliminating feedback wiring, signal conditioning equipment, and sophisticated control algorithms required for closed-loop servo systems. Manufacturing efficiency benefits include reduced inventory requirements, as the standardized NEMA 24 motor can serve multiple applications within a facility, simplifying spare parts management and reducing procurement complexity. The motor's digital control interface seamlessly integrates with modern industrial communication protocols, including Ethernet-based systems, fieldbus networks, and wireless control platforms, enabling incorporation into Industry 4.0 manufacturing environments without extensive interface development. Software compatibility extends to popular motion control programming environments, where pre-built libraries and configuration tools accelerate development timelines and reduce engineering costs associated with custom control software creation. The NEMA 24 motor's ability to operate across wide voltage ranges and accept various input signal formats enhances integration flexibility while minimizing power supply requirements and electrical infrastructure modifications. Long-term cost benefits include extended operational lifespan, minimal maintenance requirements, and energy-efficient operation that reduces ongoing operational expenses compared to alternative motor technologies requiring frequent service intervals or continuous power consumption for position holding.