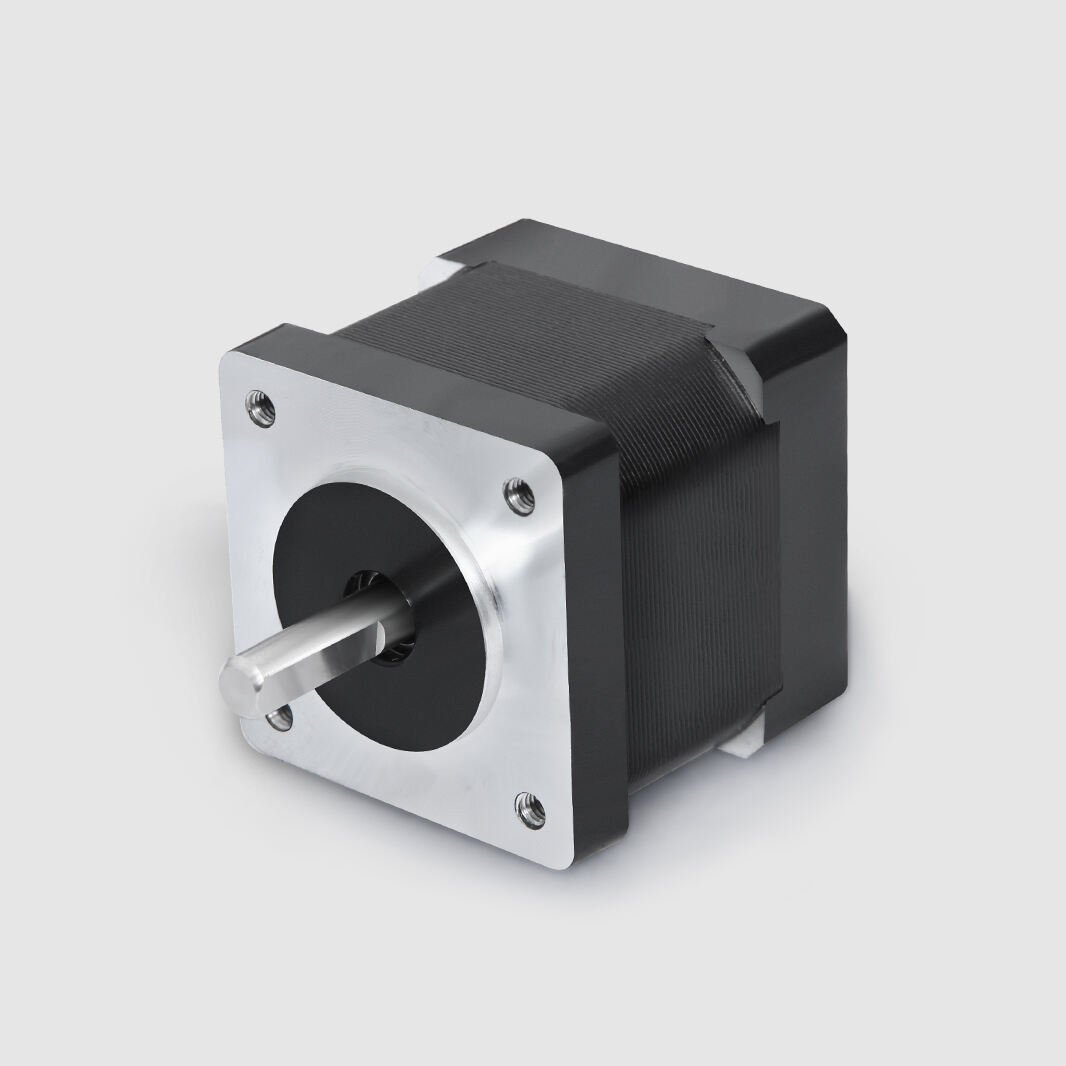

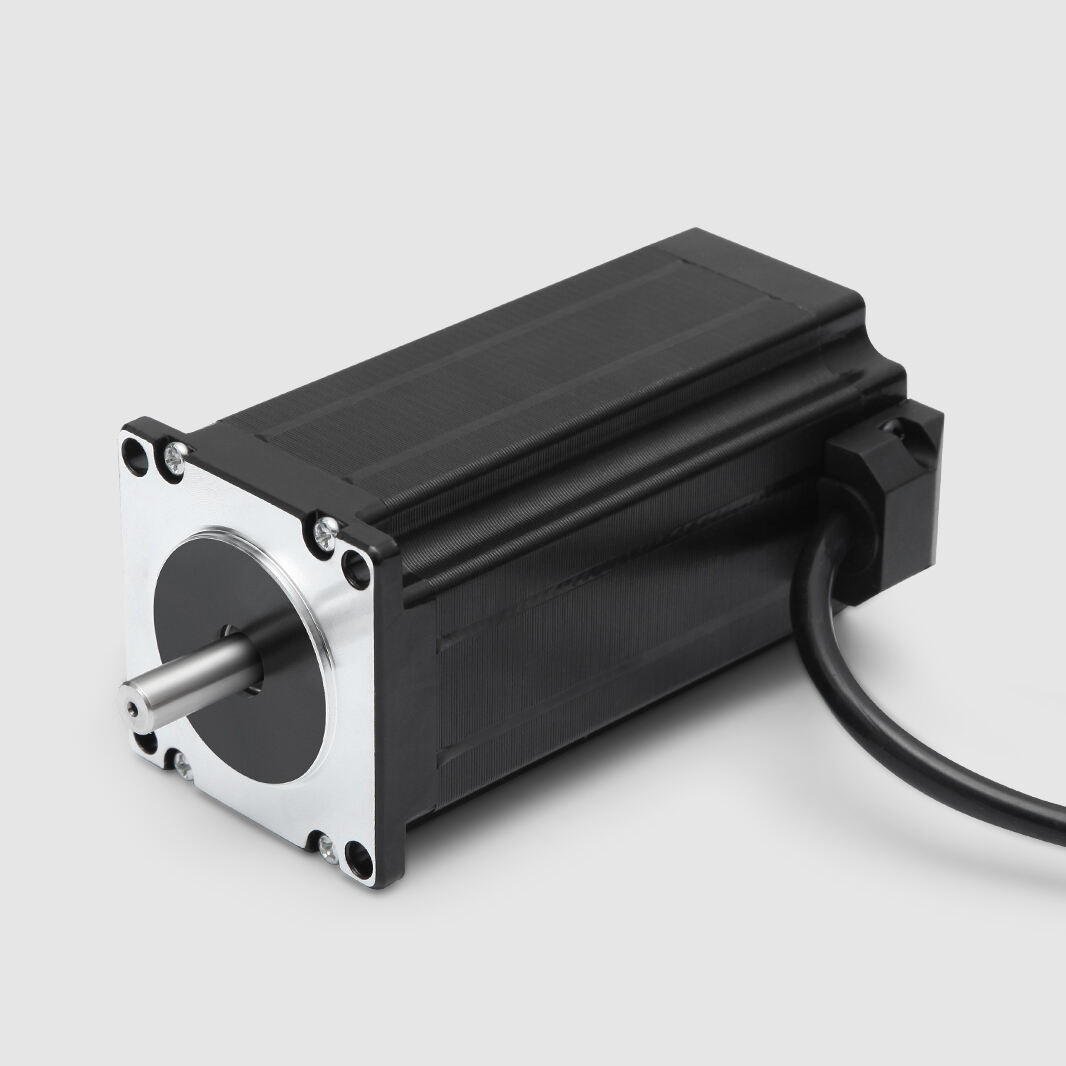

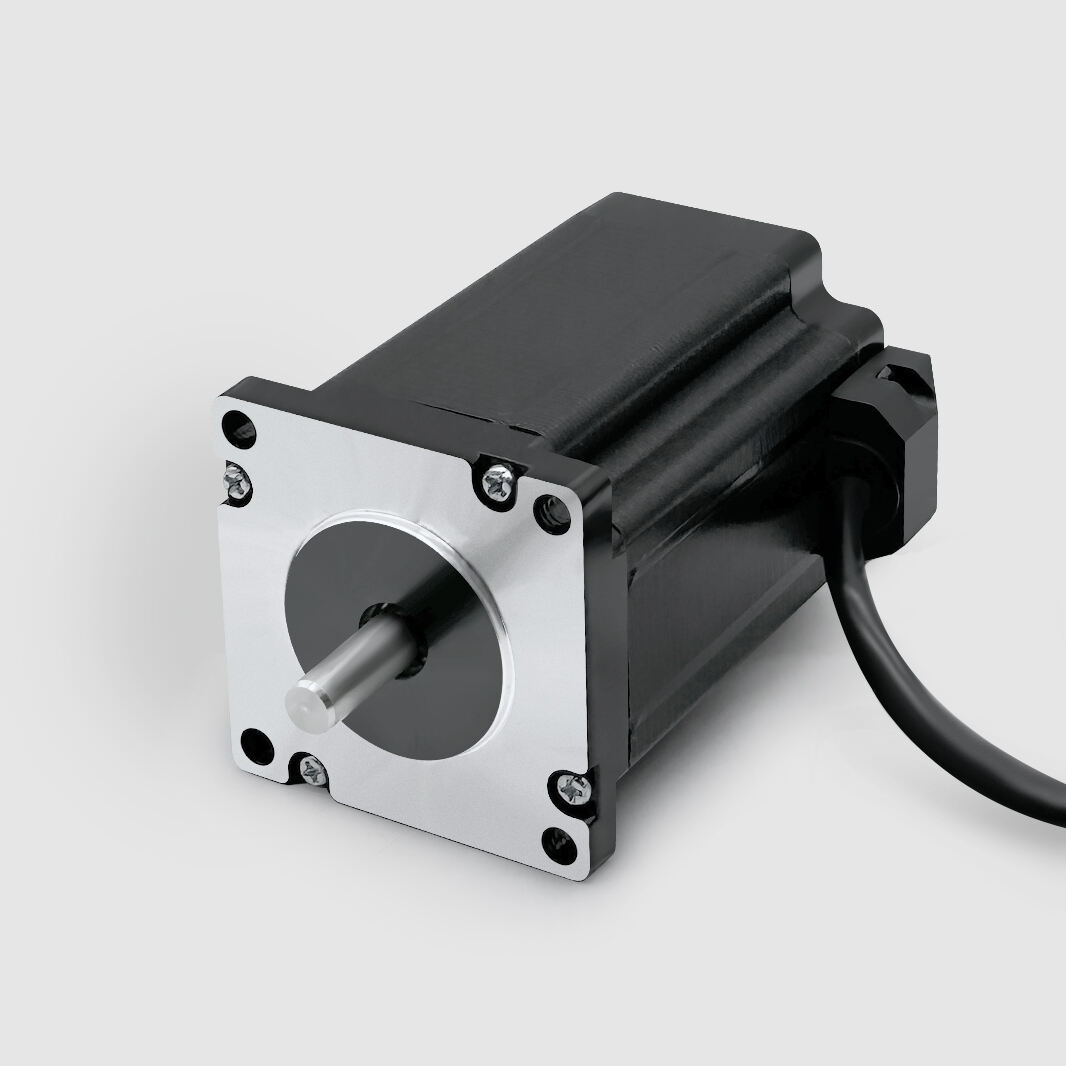

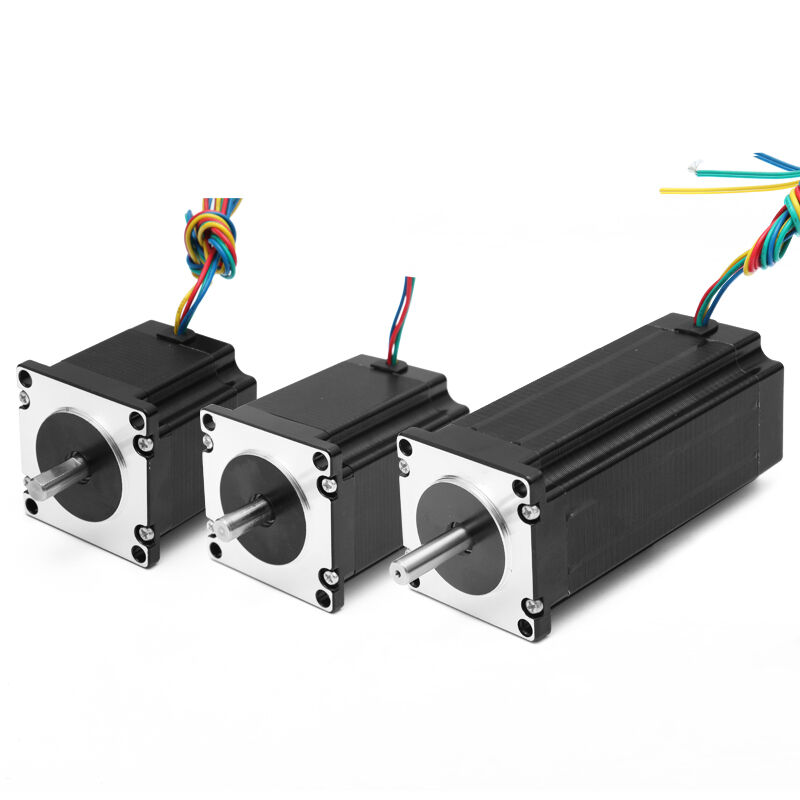

stepper motori

A stepper motori represents a revolutionary advancement in precision motor technology, delivering exceptional control and reliability across diverse industrial applications. Unlike conventional motors that rotate continuously, the stepper motori operates through discrete angular movements, allowing for precise positioning without requiring feedback systems. This innovative motor design incorporates electromagnetic principles to achieve step-by-step rotation, making it an indispensable component in automation systems worldwide. The stepper motori features multiple electromagnetic coils arranged around a rotor assembly, creating magnetic fields that attract and repel permanent magnets or magnetized teeth on the rotor. This configuration enables the motor to move in predetermined increments, typically ranging from 1.8 degrees to 15 degrees per step, depending on the specific model and construction. Modern stepper motori systems integrate advanced control electronics that manage current flow through individual coil windings, ensuring smooth operation and optimal torque delivery. The technology behind stepper motori encompasses various types, including permanent magnet, variable reluctance, and hybrid designs, each offering distinct characteristics suited to specific applications. Permanent magnet stepper motori units provide excellent holding torque and moderate step resolution, while variable reluctance models deliver higher step counts with reduced torque capabilities. Hybrid stepper motori combines the benefits of both technologies, achieving superior performance metrics that satisfy demanding industrial requirements. Applications for stepper motori span numerous industries, from 3D printing and CNC machining to robotics and medical equipment. In manufacturing environments, stepper motori drives conveyor systems, positioning mechanisms, and automated assembly lines with remarkable accuracy. The aerospace industry relies on stepper motori for satellite positioning systems and aircraft control mechanisms, where precision becomes critical for safety and performance. Additionally, stepper motori technology powers various consumer electronics, including printers, scanners, and camera lens systems, demonstrating its versatility across market segments.