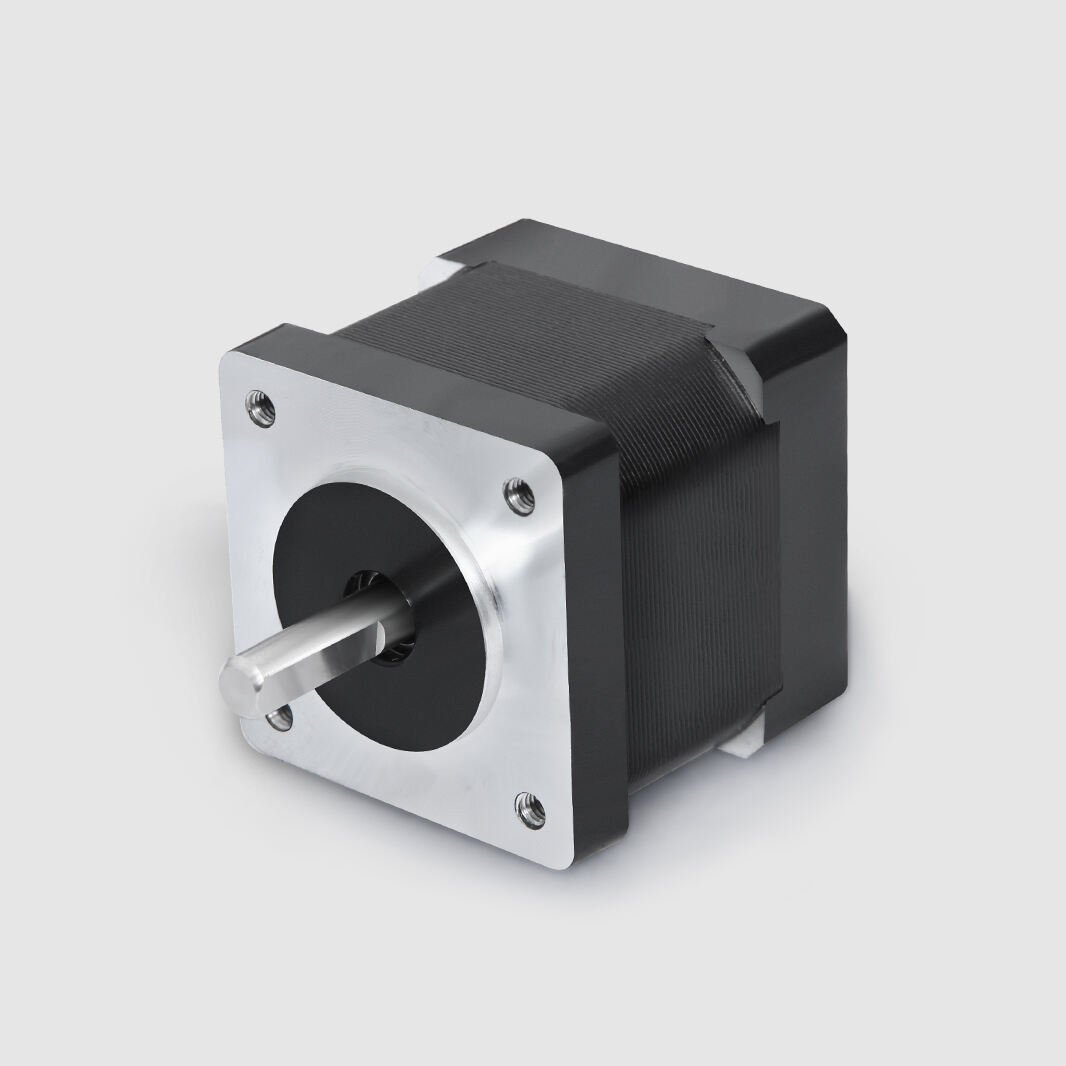

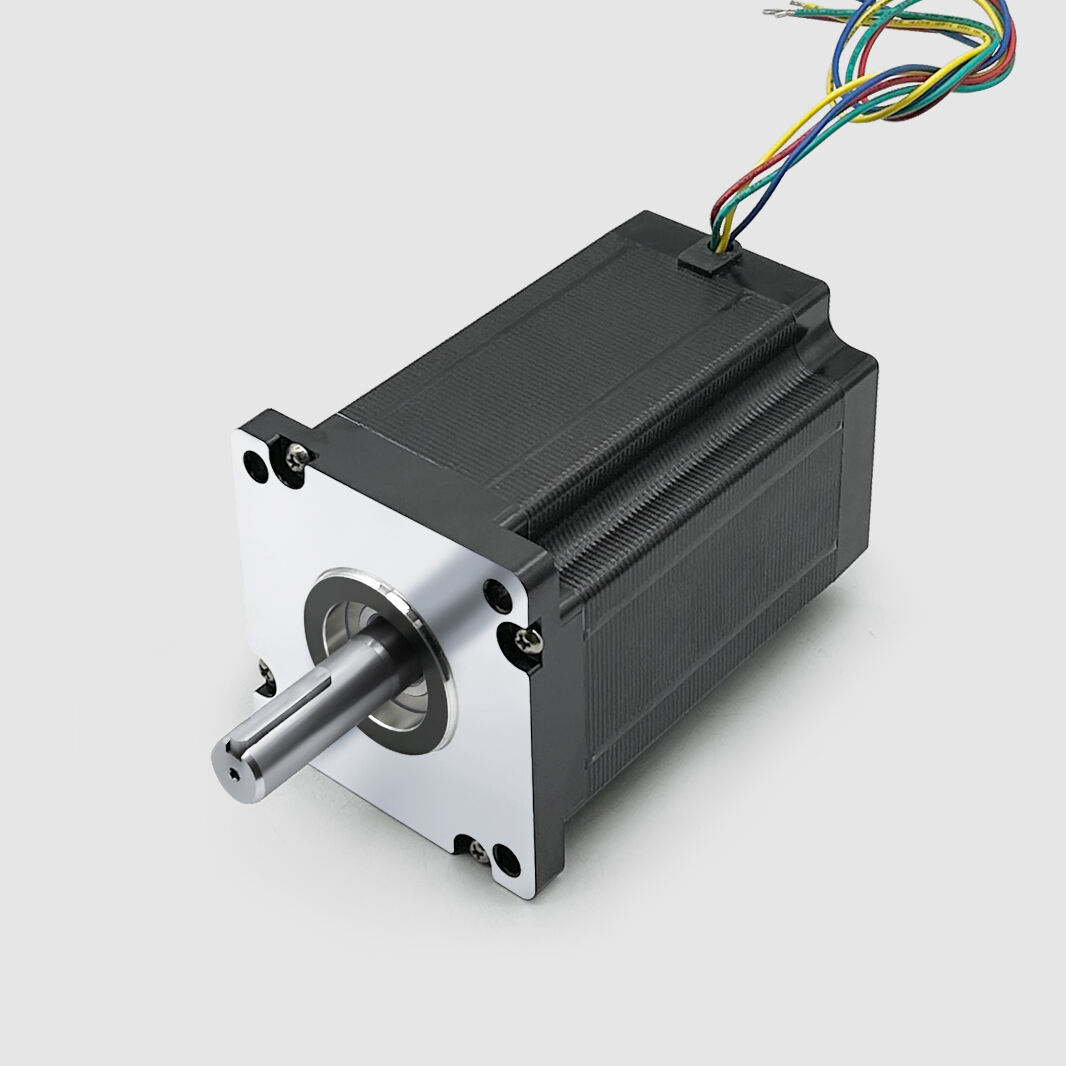

nema 17 brushless dc motor

The nema 17 brushless dc motor represents a sophisticated evolution in precision motion control technology, combining the standardized mounting dimensions of NEMA 17 specifications with advanced brushless DC motor design. This motor type measures 1.7 inches square in its faceplate dimensions, making it compatible with numerous mounting systems and applications requiring precise positioning. The brushless configuration eliminates physical brushes found in traditional DC motors, replacing them with electronic switching mechanisms that control current flow through electromagnetic windings. This design approach significantly reduces mechanical wear while enhancing operational reliability and extending service life. The nema 17 brushless dc motor operates through electronically controlled commutation, where permanent magnets on the rotor interact with precisely timed electromagnetic fields generated by stator windings. Advanced electronic speed controllers manage the switching sequence, ensuring optimal torque delivery and smooth operation across varying speed ranges. These motors typically feature three-phase winding configurations that provide balanced magnetic forces and reduced vibration during operation. The technological foundation includes high-grade neodymium permanent magnets that deliver exceptional magnetic flux density, enabling compact designs with impressive power-to-weight ratios. Modern nema 17 brushless dc motor variants incorporate hall effect sensors or encoders for precise position feedback, enabling closed-loop control systems that maintain accurate positioning even under varying load conditions. Applications span numerous industries including 3D printing, CNC machining, robotics, automated manufacturing equipment, and precision instrumentation. The standardized NEMA 17 footprint ensures easy integration into existing systems, while the brushless technology provides superior performance characteristics compared to traditional brushed alternatives. These motors excel in applications demanding high precision, consistent torque output, and minimal maintenance requirements, making them essential components in modern automation and precision motion control systems.