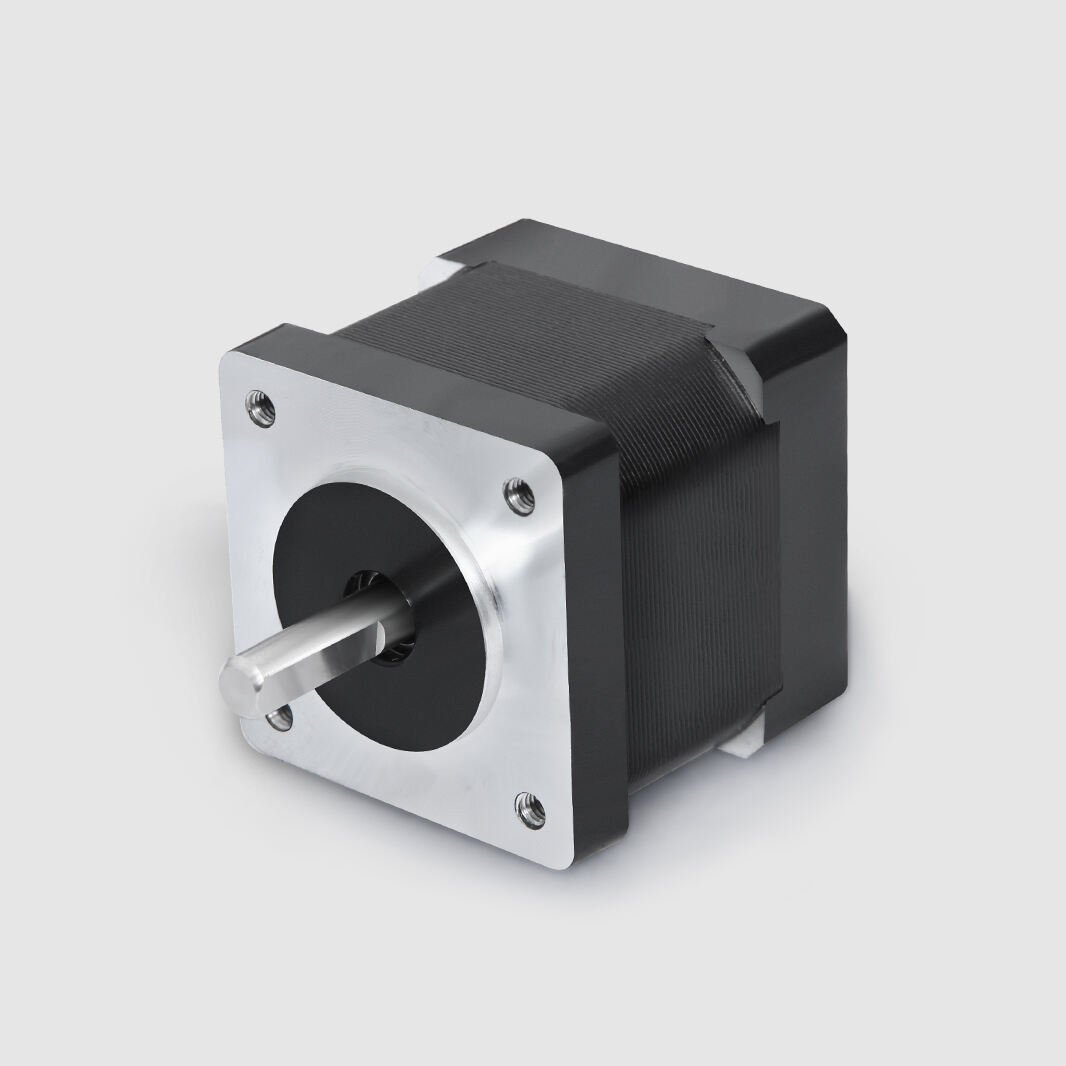

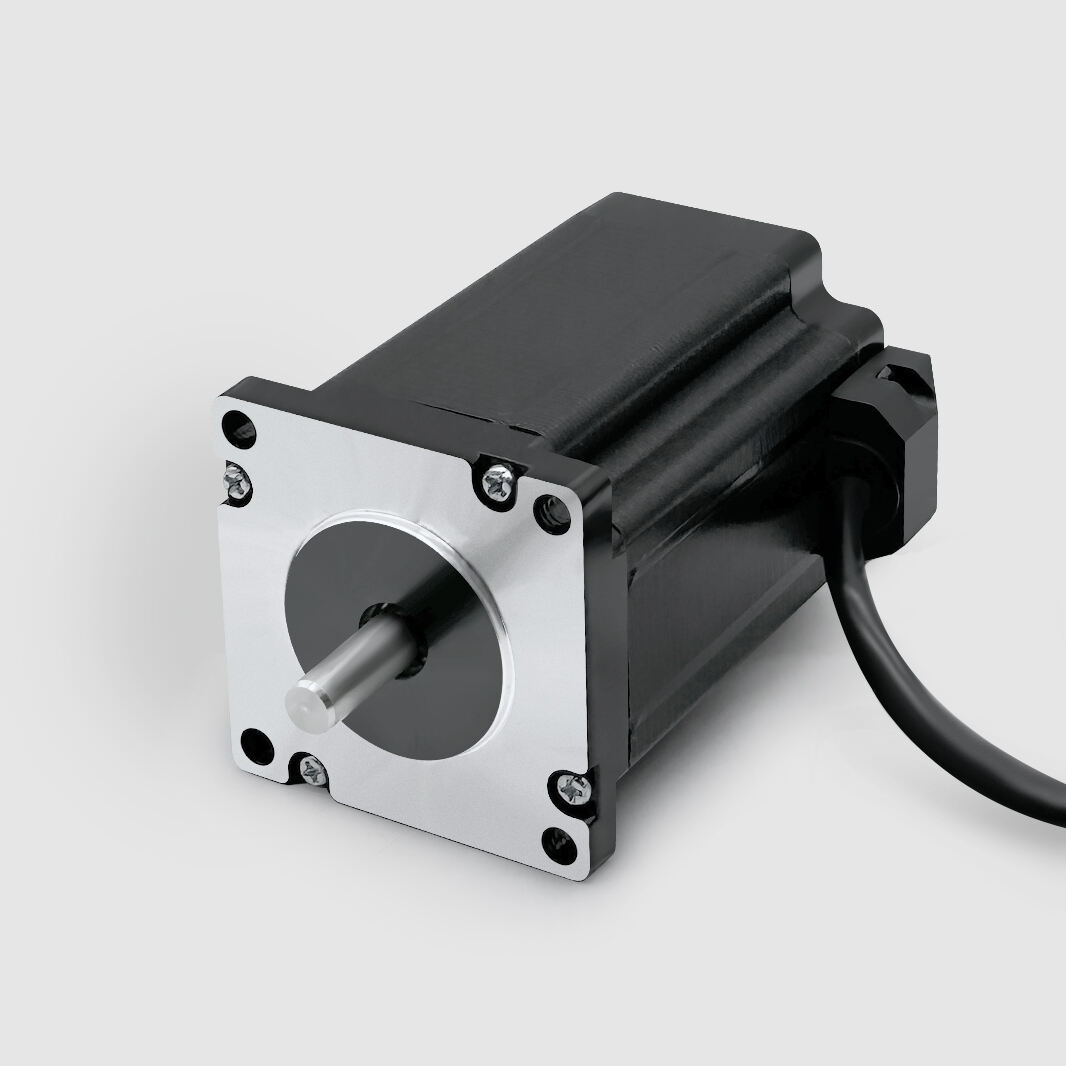

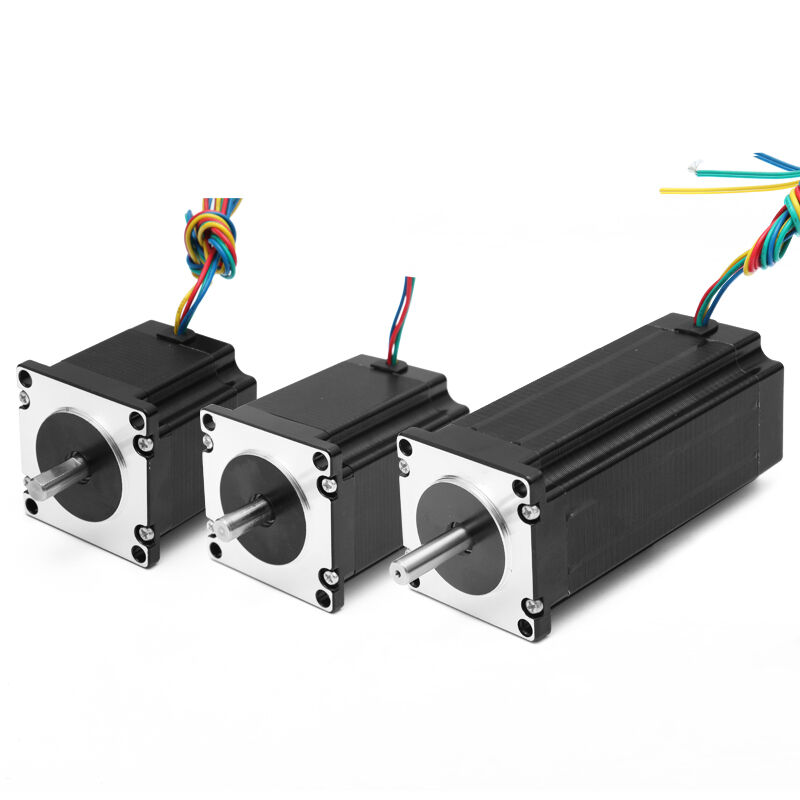

servo step

The servo step represents a revolutionary advancement in precision motion control technology, combining the exceptional accuracy of servo motors with the discrete positioning capabilities of stepper systems. This sophisticated device operates by utilizing closed-loop feedback control mechanisms that continuously monitor and adjust position, velocity, and torque parameters to achieve unprecedented levels of accuracy and repeatability. Unlike traditional stepper motors that operate in open-loop configurations, the servo step integrates advanced encoder feedback systems that provide real-time position verification and error correction capabilities. The core functionality revolves around intelligent control algorithms that process feedback signals from high-resolution encoders, enabling the system to detect and compensate for any positional deviations instantaneously. This technological innovation eliminates the common issues associated with conventional stepping systems, such as step loss, resonance problems, and reduced performance at higher speeds. The servo step employs sophisticated microprocessor-based controllers that manage complex motion profiles while maintaining optimal performance across varying load conditions. Key technological features include adaptive current control, anti-resonance algorithms, and dynamic torque optimization that collectively enhance operational efficiency. The device incorporates advanced digital signal processing capabilities that enable smooth motion interpolation and precise trajectory control for complex multi-axis applications. Primary applications span across industrial automation, CNC machinery, 3D printing systems, robotic platforms, packaging equipment, and laboratory instrumentation where precision positioning is critical. In manufacturing environments, servo step technology proves invaluable for assembly line automation, quality control systems, and material handling applications that demand consistent repeatability. The medical device industry extensively utilizes servo step systems in surgical robots, diagnostic equipment, and pharmaceutical manufacturing processes where precision directly impacts safety and efficacy. Additionally, aerospace and defense sectors rely on servo step technology for satellite positioning systems, radar equipment, and precision measurement instruments that require exceptional accuracy under demanding environmental conditions.