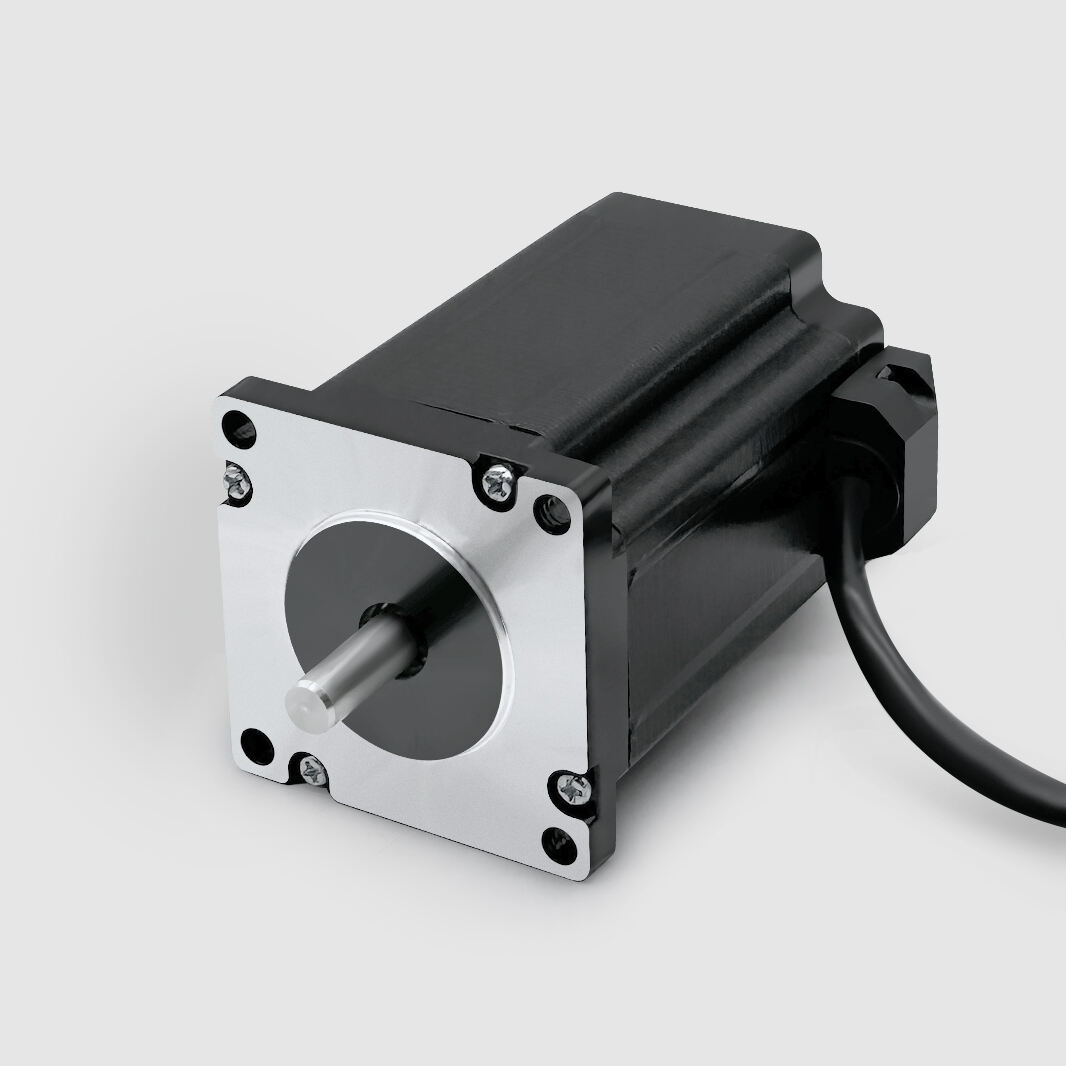

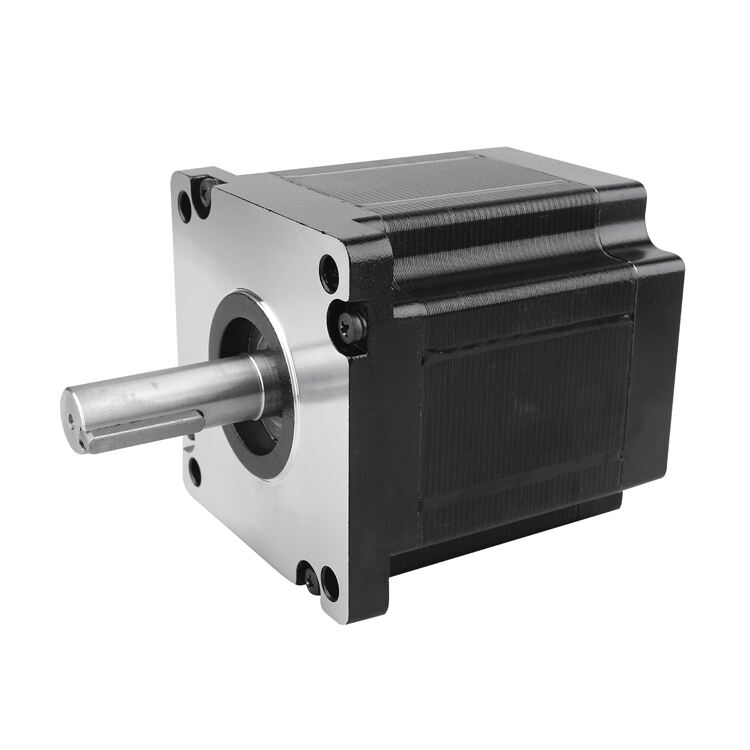

42 34 stepper motor

The 42 34 stepper motor represents a compact yet powerful solution in precision motion control applications. This NEMA 17 standard stepper motor features a 42mm square frame with a 34mm body length, making it ideal for space-constrained environments while maintaining exceptional performance characteristics. The 42 34 stepper motor operates on the fundamental principle of electromagnetic field rotation, converting digital pulse signals into precise angular movements without requiring feedback systems. Its bipolar configuration typically delivers 200 steps per revolution, providing 1.8-degree step angles for accurate positioning control. The motor incorporates high-quality permanent magnets and precision-wound copper coils that ensure consistent torque output and minimal vibration during operation. Key technological features include excellent holding torque capabilities, typically ranging from 0.3 to 0.6 Nm depending on the specific model variant. The 42 34 stepper motor supports various voltage ratings, commonly operating at 12V, 24V, or 48V systems, making it compatible with diverse control electronics. Its construction utilizes durable materials including steel rotors and high-temperature insulation systems that enable reliable operation in industrial environments. The motor shaft diameter typically measures 5mm with D-cut or round configurations to accommodate different coupling mechanisms. Temperature resistance characteristics allow continuous operation in ambient conditions ranging from -20°C to +80°C. The 42 34 stepper motor finds extensive applications across multiple industries including 3D printing, CNC machining, automated assembly lines, robotics, camera positioning systems, and laboratory equipment. Its compact dimensions make it particularly suitable for portable devices and desktop manufacturing equipment. The motor excels in applications requiring precise positioning, consistent repeatability, and reliable operation without complex control algorithms. Medical device manufacturers frequently specify this motor for surgical equipment and diagnostic instruments due to its quiet operation and precise control capabilities.