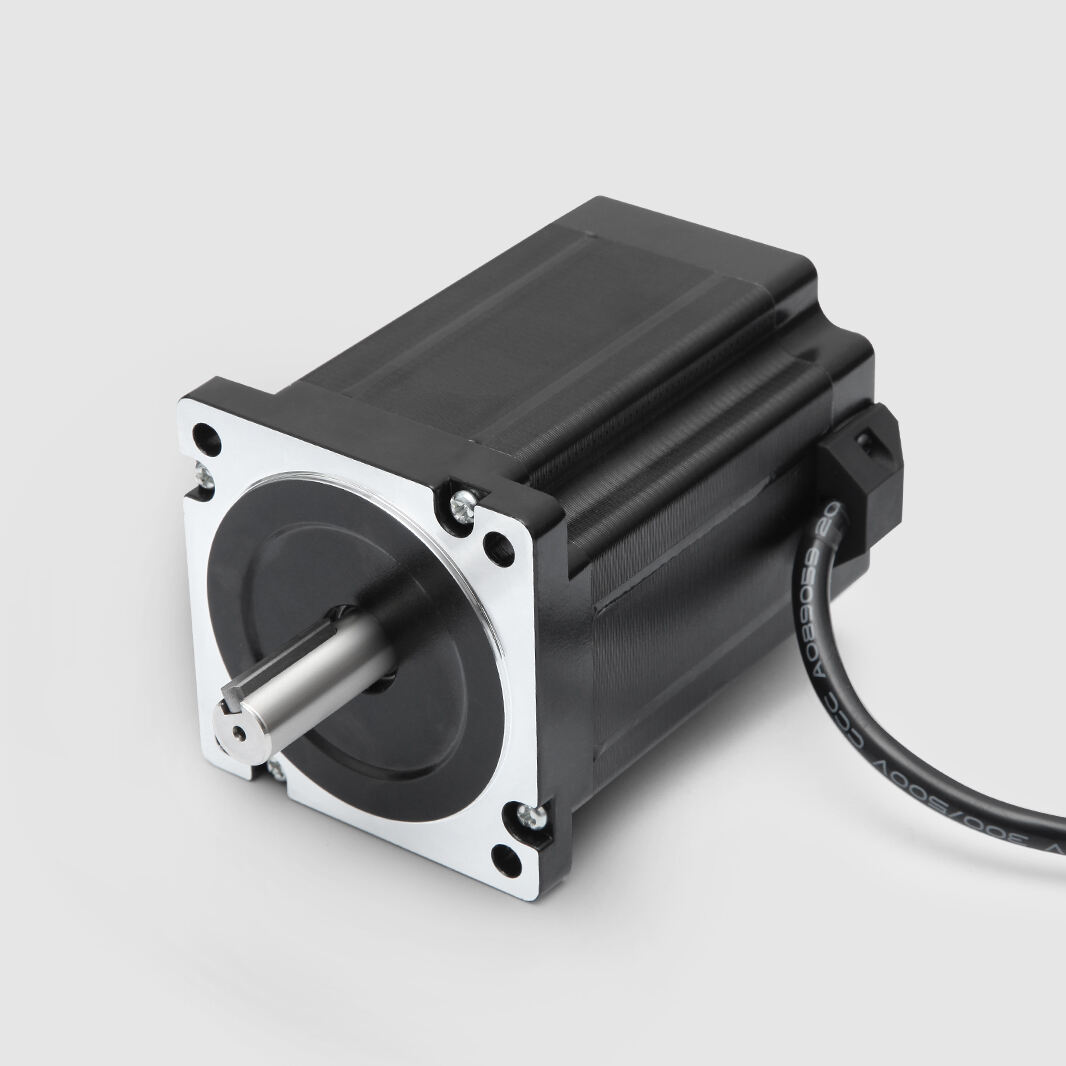

linear rail stepper motor

A linear rail stepper motor represents an innovative fusion of precision linear motion technology and stepper motor control systems, designed to deliver exceptional accuracy in automated applications. This sophisticated electromechanical device combines a stepper motor with an integrated linear rail system, creating a compact solution that converts rotational motion into precise linear displacement. The linear rail stepper motor operates through electromagnetic principles, where electrical pulses control the motor's rotation, which subsequently drives a lead screw or belt mechanism along a precision-engineered rail system. The main functions of this advanced system include providing controlled linear movement with excellent repeatability, maintaining consistent positioning accuracy across extended operational cycles, and delivering reliable performance in demanding industrial environments. The technological features of linear rail stepper motors encompass high-resolution positioning capabilities, typically achieving micron-level accuracy, robust construction materials that ensure longevity, and sophisticated feedback systems that monitor position and velocity. These motors incorporate precision ball bearings or linear guides that minimize friction and wear, while advanced magnetic circuits optimize torque delivery throughout the operational range. The integrated design eliminates the need for separate mounting hardware, reducing installation complexity and system footprint. Linear rail stepper motors find extensive applications across diverse industries, including automated manufacturing systems, laboratory equipment, medical devices, packaging machinery, and precision measurement instruments. In semiconductor manufacturing, these motors enable precise wafer positioning and component placement. Medical applications utilize their accuracy for diagnostic equipment and surgical robotics. The packaging industry benefits from their consistent performance in filling, sealing, and labeling operations. Research facilities employ linear rail stepper motors in analytical instruments and testing equipment where repeatability is crucial. Their versatility extends to 3D printing systems, CNC machinery, and automated assembly lines, making them indispensable components in modern industrial automation.