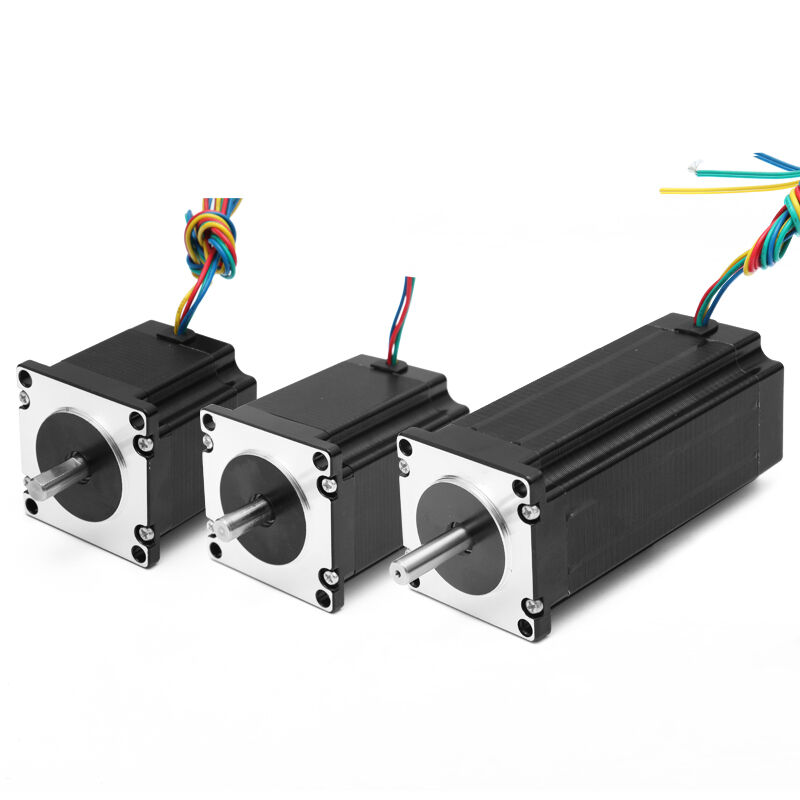

Advanced Digital Control Integration and Versatility

Strong stepper motor systems excel in digital control integration, offering unparalleled versatility and compatibility with modern automation platforms through sophisticated control interfaces and communication protocols. The native digital pulse and direction control simplifies programming and interfacing with virtually any control system, from simple microcontroller circuits to complex industrial automation networks. Advanced driver electronics incorporate multiple control modes including full-step, half-step, and microstepping operation up to 256 subdivisions per full step, enabling smooth motion profiles and precise positioning resolution. The integrated communication capabilities support popular industrial protocols such as Modbus RTU, CANopen, EtherCAT, and Profinet, facilitating seamless integration into existing factory automation infrastructure without requiring protocol converters or additional interface hardware. Real-time parameter adjustment capabilities allow operators to optimize motor performance for specific applications through software configuration, including current regulation, velocity profiles, acceleration rates, and holding current reduction for energy efficiency. The intelligent driver systems feature built-in protection mechanisms including overcurrent detection, thermal monitoring, and stall detection that prevent damage while providing diagnostic feedback to control systems for predictive maintenance scheduling. Multi-axis coordination capabilities enable synchronized motion control across multiple strong stepper motor axes, essential for applications such as gantry systems, pick-and-place robots, and coordinated material handling equipment. The programmable input/output functions provide additional flexibility for integrating limit switches, sensors, and auxiliary equipment directly through the motor driver, reducing wiring complexity and installation costs. Advanced motion profiles including S-curve acceleration, linear interpolation, and circular interpolation are supported natively, eliminating the need for external motion controllers in many applications. The control resolution capabilities extend beyond basic positioning to include speed regulation, torque control, and even closed-loop operation when paired with optional encoder feedback, providing the flexibility to adapt to evolving application requirements. Remote monitoring and configuration capabilities through Ethernet connectivity enable predictive maintenance, performance optimization, and troubleshooting from central control rooms, reducing on-site service requirements and improving overall equipment effectiveness.