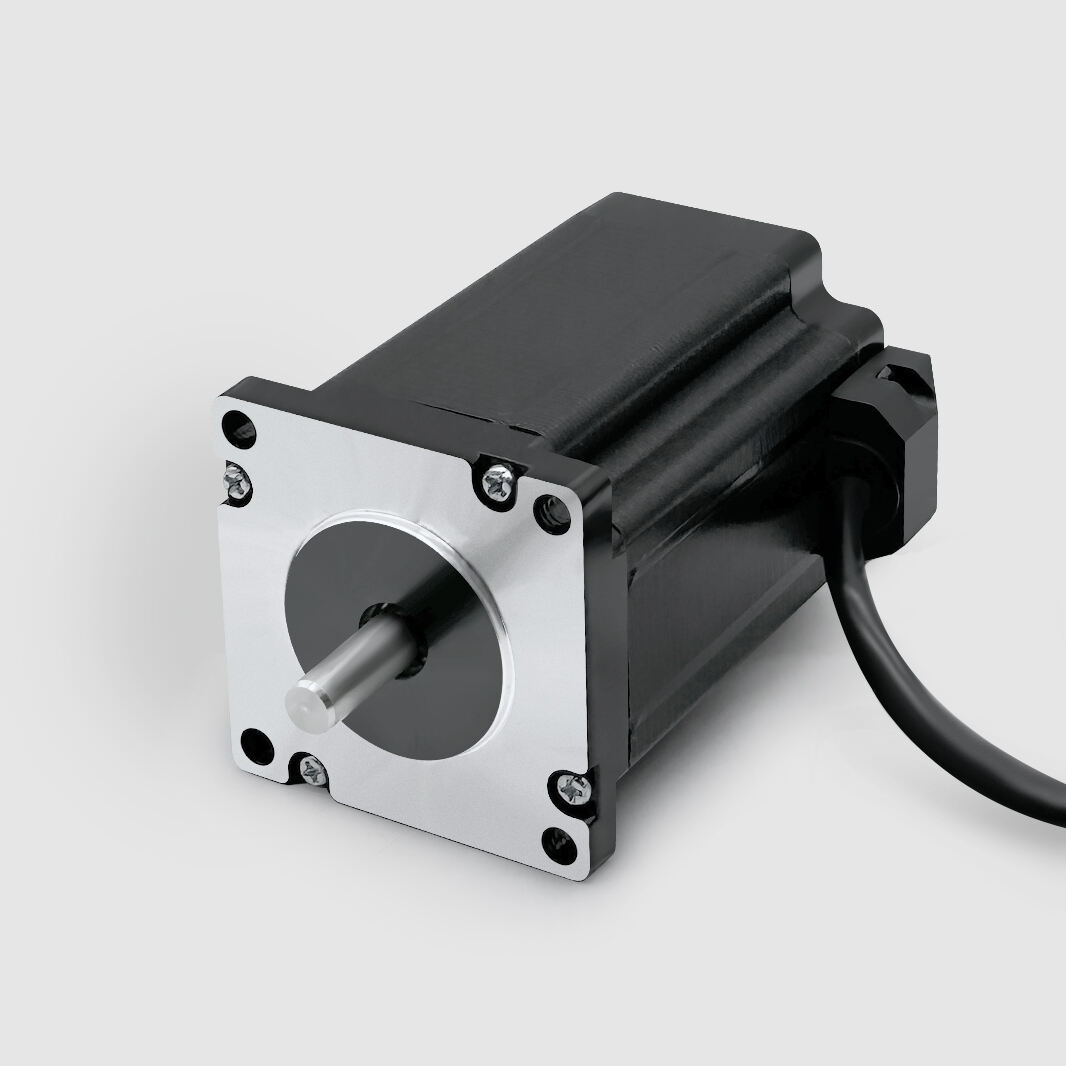

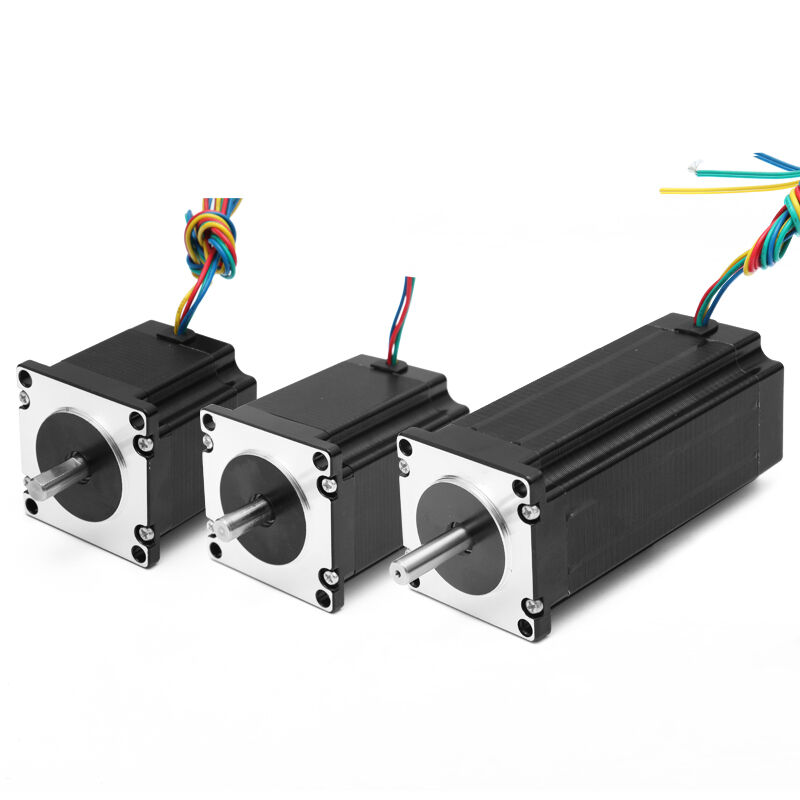

high quality stepper motors

High quality stepper motors represent a revolutionary advancement in precision motion control technology, delivering exceptional performance across diverse industrial applications. These sophisticated electrical devices convert digital pulses into precise mechanical rotation, enabling accurate positioning without the need for feedback systems. The fundamental operation of high quality stepper motors involves electromagnetic coils that energize in sequence, creating controlled magnetic fields that rotate the motor shaft in discrete steps. This unique mechanism allows for exact angular positioning, typically ranging from 1.8 to 0.9 degrees per step, ensuring remarkable precision in motion control applications. The technological architecture of high quality stepper motors incorporates advanced materials and engineering innovations that enhance durability, reduce vibration, and improve overall efficiency. Modern designs feature optimized rotor configurations, premium magnetic materials, and precision-machined components that work together to deliver smooth, reliable operation. These motors excel in applications requiring precise positioning, consistent torque delivery, and repeatable motion patterns. The versatility of high quality stepper motors makes them indispensable in numerous industries, including 3D printing, CNC machining, robotics, medical equipment, automotive systems, and aerospace applications. Their ability to maintain position without power consumption, combined with excellent low-speed torque characteristics, makes them ideal for applications demanding accuracy and reliability. The integration of advanced driver technologies further enhances the performance of high quality stepper motors, enabling microstepping capabilities that significantly improve resolution and reduce mechanical resonance. These motors offer superior holding torque, ensuring stable positioning even under external forces, while their open-loop control system simplifies implementation and reduces overall system complexity compared to servo motors requiring feedback mechanisms.