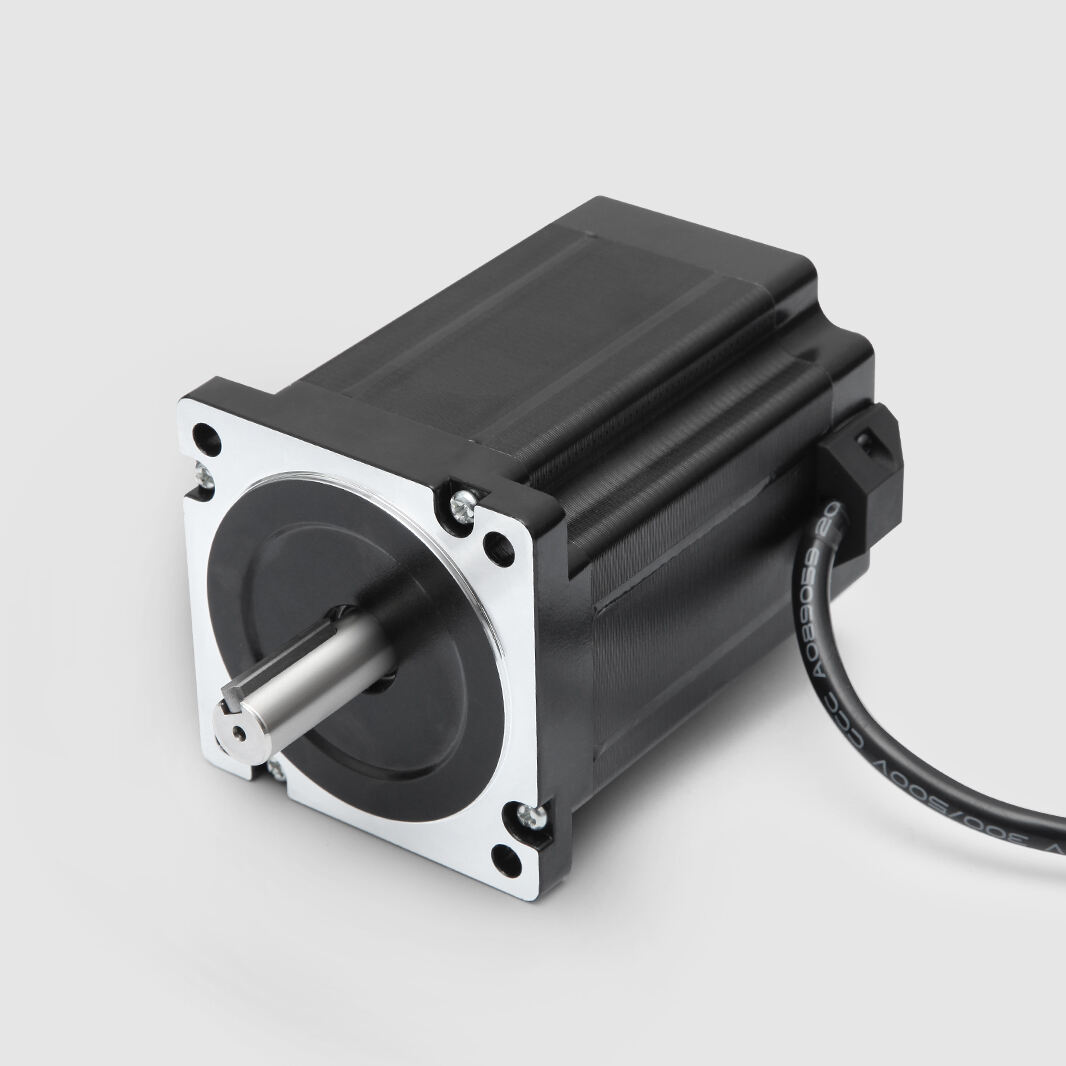

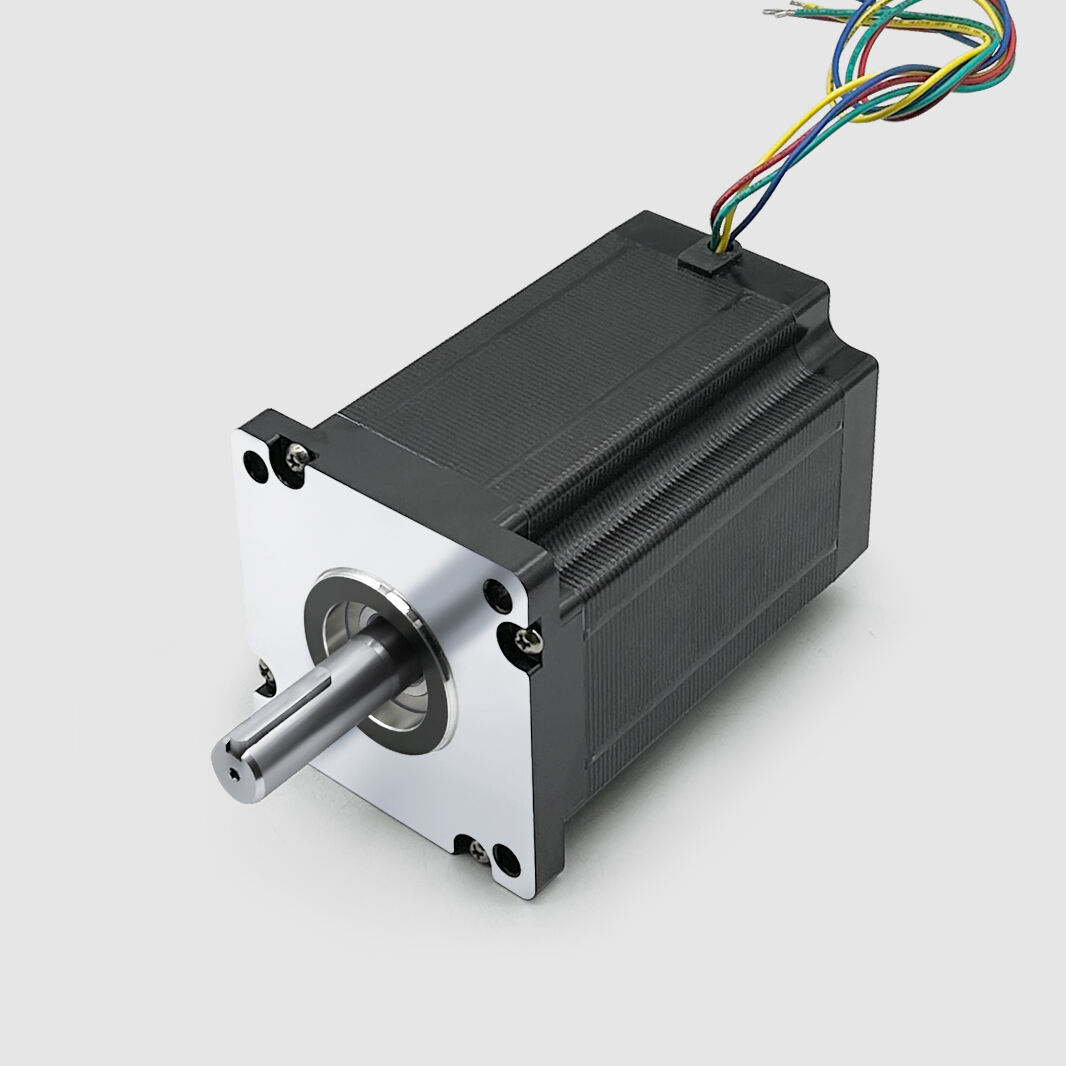

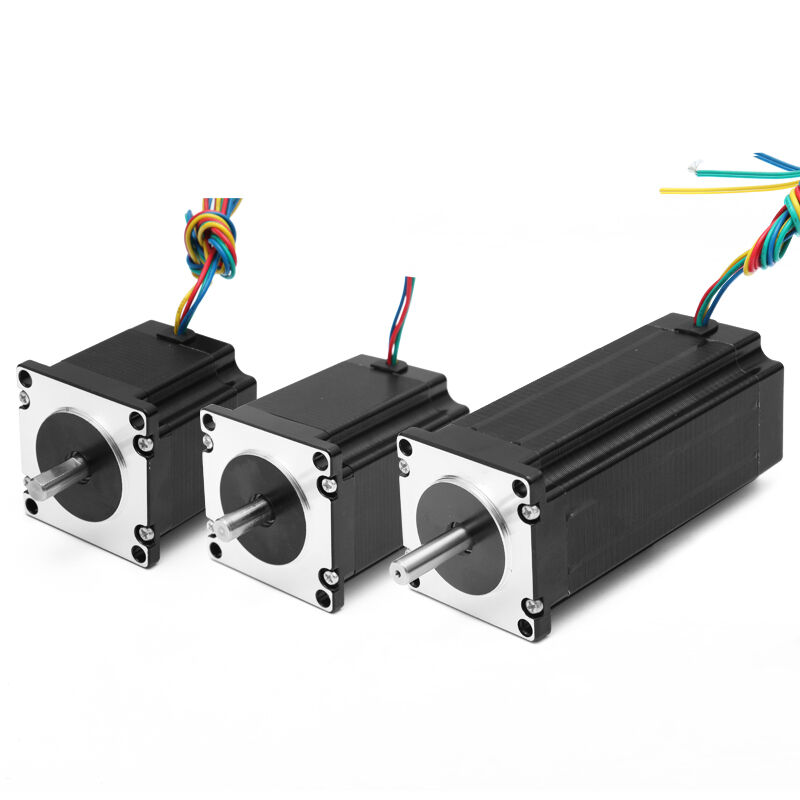

step in motor

A step in motor, commonly known as a stepper motor, represents a sophisticated electromechanical device that converts electrical pulses into precise mechanical rotation. This innovative technology divides a complete rotation into numerous discrete steps, enabling exceptional position control without requiring feedback systems. The step in motor operates by energizing electromagnetic coils in a specific sequence, creating magnetic fields that rotate the motor shaft in predetermined increments. Each electrical pulse corresponds to a fixed angular displacement, typically ranging from 0.9 to 15 degrees per step, depending on the motor design and configuration. The fundamental principle behind step in motor functionality involves the interaction between permanent magnets on the rotor and electromagnets on the stator. When electrical current flows through the stator windings in a controlled pattern, it generates magnetic forces that attract and repel the rotor magnets, causing precise rotational movement. This controlled stepping action makes the step in motor ideal for applications requiring accurate positioning, controlled speed, and repeatable motion. Modern step in motor designs incorporate advanced materials and manufacturing techniques to enhance performance characteristics. High-quality permanent magnets, precision-engineered components, and optimized winding configurations contribute to improved torque output, reduced noise levels, and enhanced reliability. The step in motor finds extensive applications across diverse industries, including 3D printing, CNC machinery, robotics, medical equipment, and automated manufacturing systems. In 3D printing applications, the step in motor provides the precise movement control necessary for accurate layer deposition and dimensional accuracy. CNC machines utilize step in motor technology to achieve exact tool positioning and consistent cutting operations. Robotics applications benefit from the step in motor's ability to provide controlled joint movement and precise manipulator positioning. Medical devices such as infusion pumps, diagnostic equipment, and surgical instruments rely on step in motor technology for safe and accurate operation. The versatility of step in motor systems extends to consumer electronics, automotive applications, and aerospace systems, where precise motion control remains critical for optimal performance and safety.