stepper motor driver 3d printer

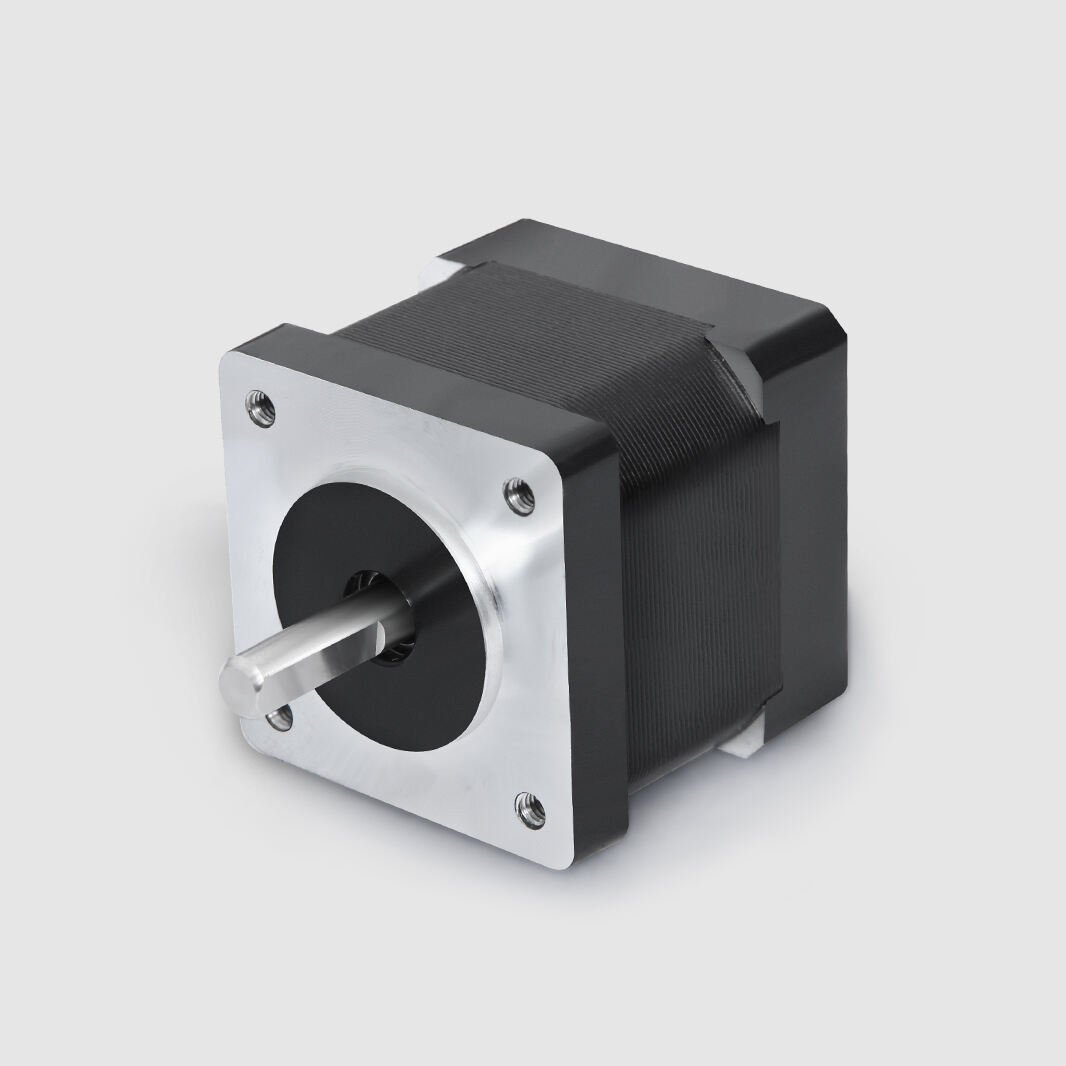

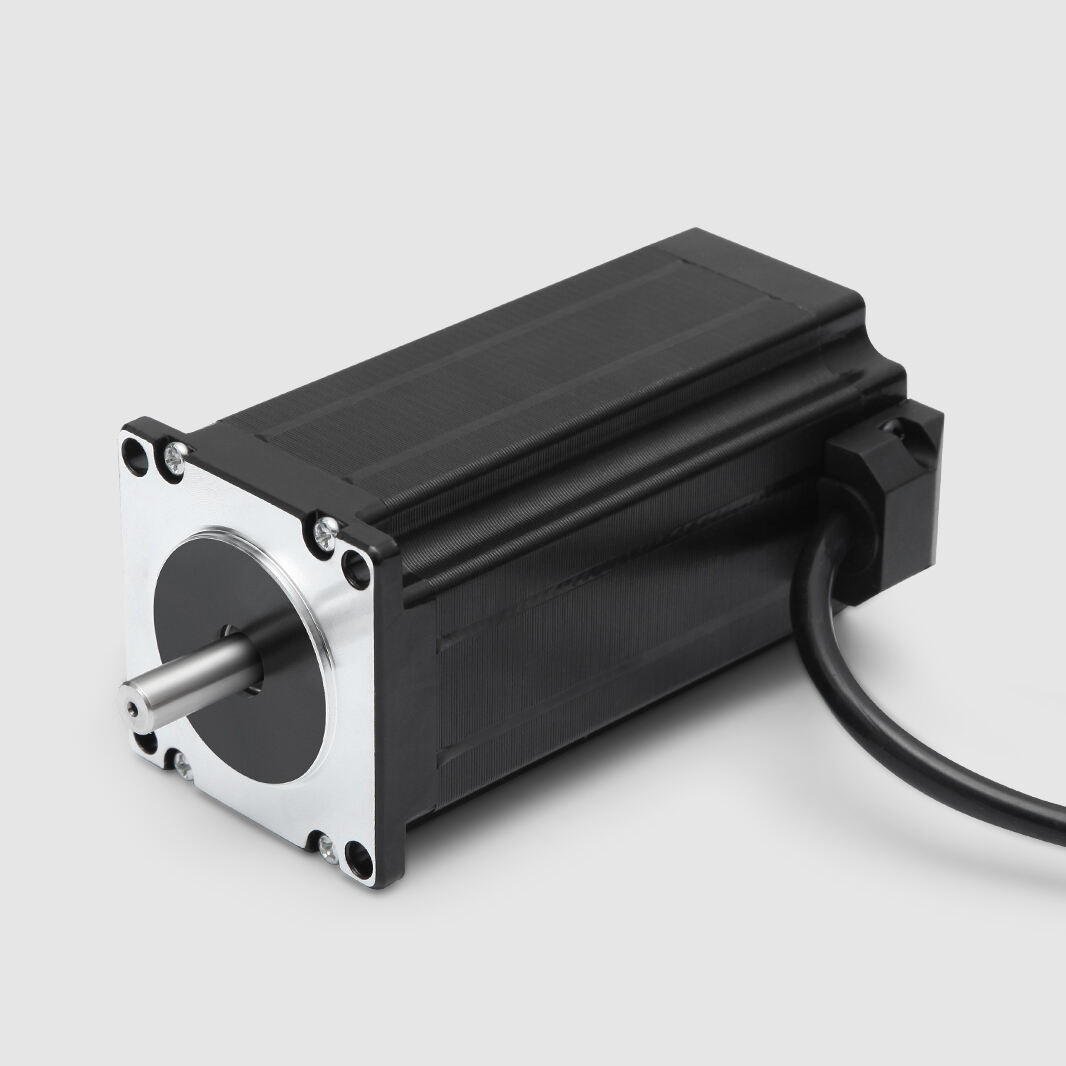

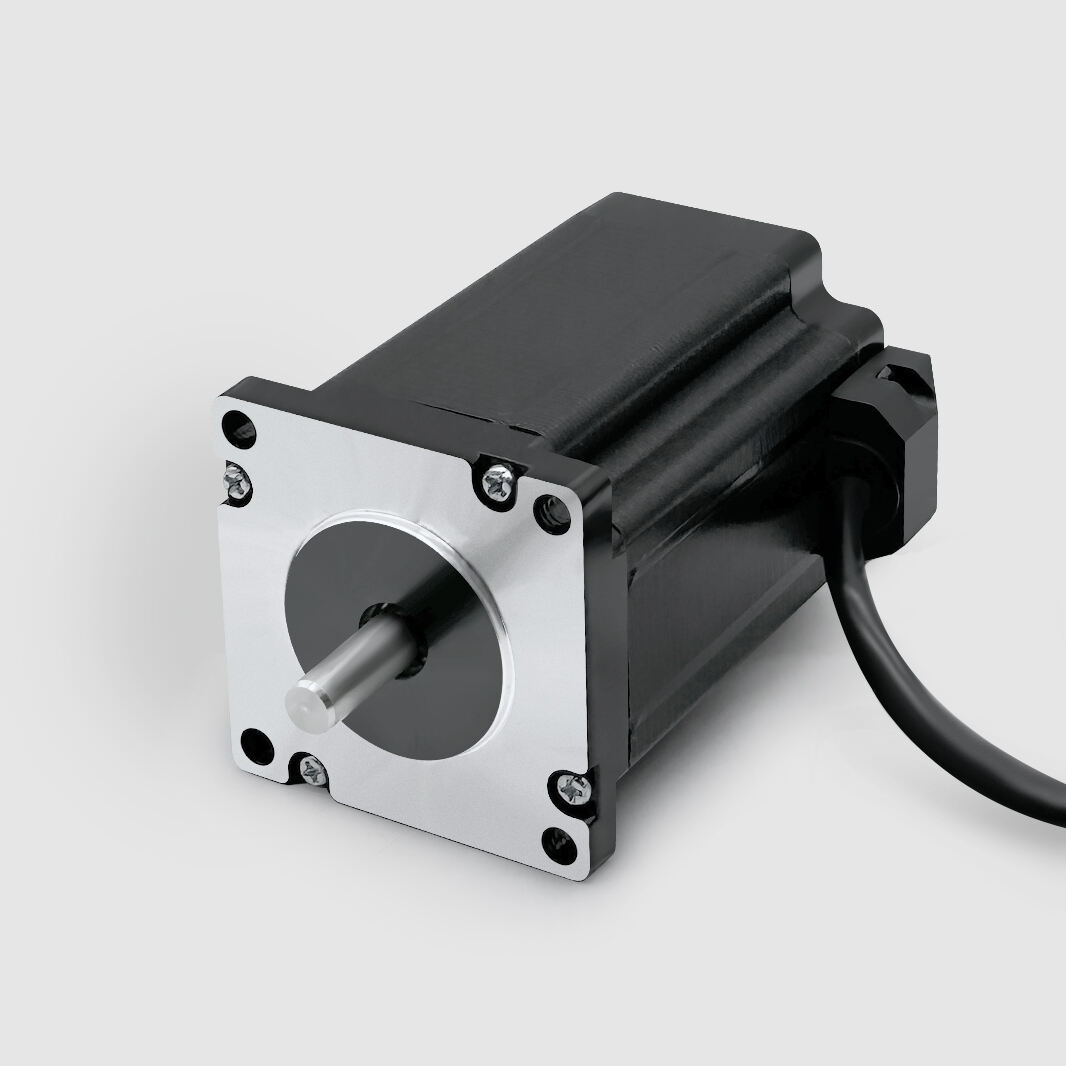

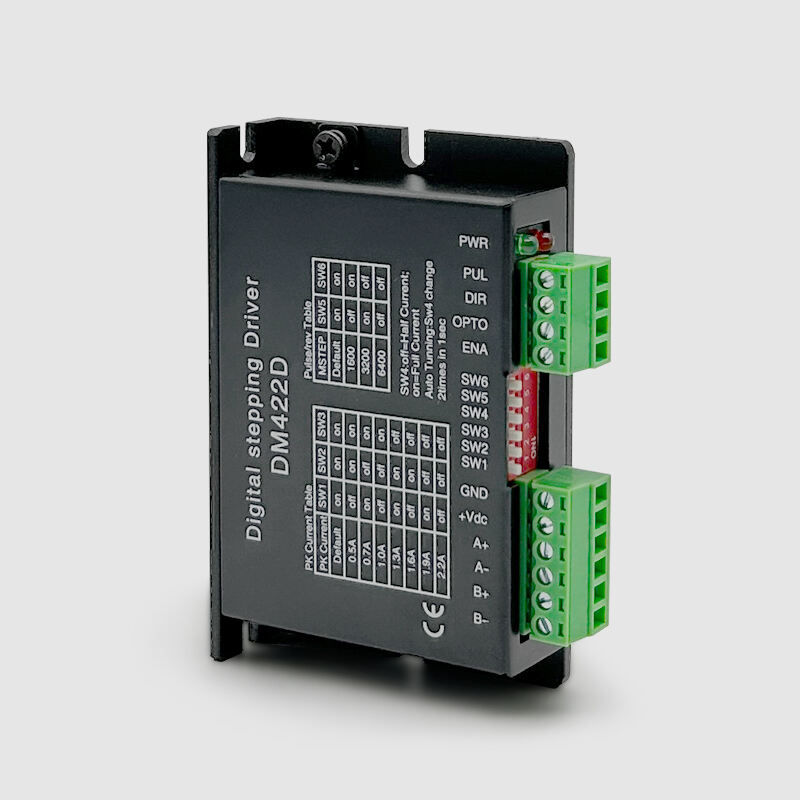

A stepper motor driver 3d printer represents a sophisticated additive manufacturing system that utilizes precise stepper motor control technology to create three-dimensional objects layer by layer. This advanced printing solution integrates specialized motor drivers that convert digital pulses into exact rotational movements, enabling exceptional positioning accuracy and repeatable performance across all printing axes. The stepper motor driver 3d printer operates through coordinated movement of multiple stepper motors that control the extruder head, build platform, and filament feeding mechanisms with remarkable precision. These systems feature microstepping capabilities that divide each motor step into smaller increments, resulting in smoother motion profiles and enhanced surface quality in printed parts. The technological foundation of a stepper motor driver 3d printer includes advanced control boards that manage motor current, acceleration profiles, and thermal protection to ensure consistent operation during extended printing sessions. Modern implementations incorporate silent stepper drivers that significantly reduce operational noise while maintaining torque output and positional accuracy. The driver circuitry provides precise current regulation that optimizes motor performance while preventing overheating and ensuring longevity of mechanical components. Applications for stepper motor driver 3d printer technology span numerous industries including prototyping, manufacturing, education, healthcare, and consumer markets. These systems excel in producing functional prototypes, custom tooling, architectural models, medical devices, and end-use parts that require dimensional accuracy and surface finish quality. The versatility of stepper motor driver 3d printer systems allows them to process various thermoplastic materials including PLA, ABS, PETG, and specialized engineering filaments. Professional applications leverage the precision capabilities for producing jigs, fixtures, and low-volume production parts that meet stringent quality requirements. Educational institutions utilize these systems for STEM programs and engineering curriculum development, while hobbyists appreciate the reliability and consistent results achievable with properly calibrated stepper motor driver 3d printer configurations.