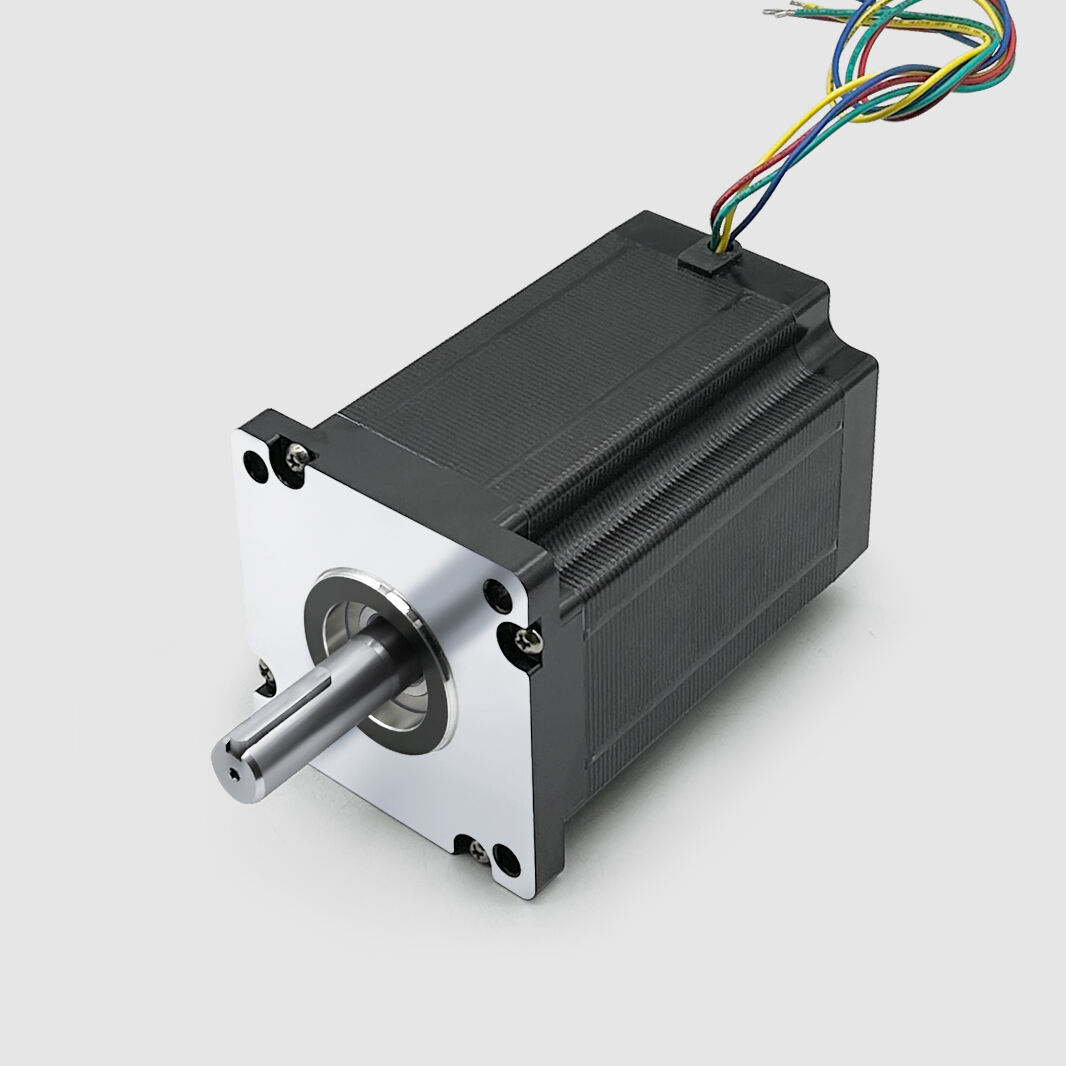

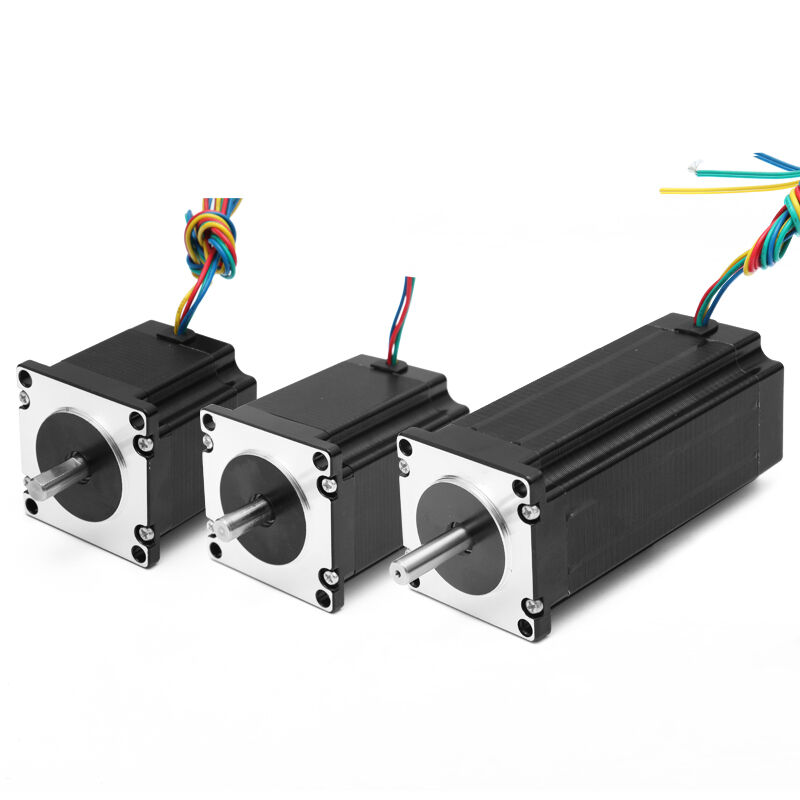

Versatile Application Compatibility and Integration Ease

The motor dc stepper offers unparalleled versatility in application compatibility, seamlessly integrating into diverse industrial, commercial, and scientific systems while adapting to various operational requirements and environmental conditions. This exceptional flexibility stems from the motor dc stepper's standardized mounting configurations, universal control interfaces, and scalable performance characteristics that accommodate applications ranging from micro-positioning systems to heavy-duty industrial machinery. Engineers appreciate how the motor dc stepper simplifies system design through its compatibility with standard digital control signals, eliminating the need for specialized interface electronics or complex analog signal conditioning equipment. The motor dc stepper's modular design philosophy enables easy customization through various shaft configurations, mounting options, and electrical specifications that match specific application requirements without requiring extensive mechanical modifications. Manufacturing environments benefit from the motor dc stepper's robust construction that withstands industrial conditions including vibration, temperature fluctuations, and electromagnetic interference while maintaining consistent performance standards. The motor dc stepper's compact form factor allows integration into space-constrained applications such as portable instruments, desktop automation equipment, and embedded systems where size limitations traditionally restrict motor selection options. Rapid prototyping processes accelerate significantly with motor dc stepper technology, as engineers can quickly evaluate different performance parameters and mechanical configurations without waiting for custom motor designs or specialized components. The motor dc stepper's standardized electrical interfaces ensure compatibility with existing control systems, programmable logic controllers, and motion control hardware, reducing integration time and development costs for new projects. Maintenance procedures remain straightforward with motor dc stepper systems, as technicians can easily replace units without requiring specialized tools, alignment procedures, or calibration equipment that complicate service operations. International compatibility standards ensure that motor dc stepper units from different manufacturers maintain interchangeable mounting dimensions and electrical specifications, providing supply chain flexibility and reducing inventory management complexity. The motor dc stepper's proven reliability across diverse applications builds confidence in system designers who require consistent performance across multiple product lines and operational environments while maintaining cost-effective solutions.