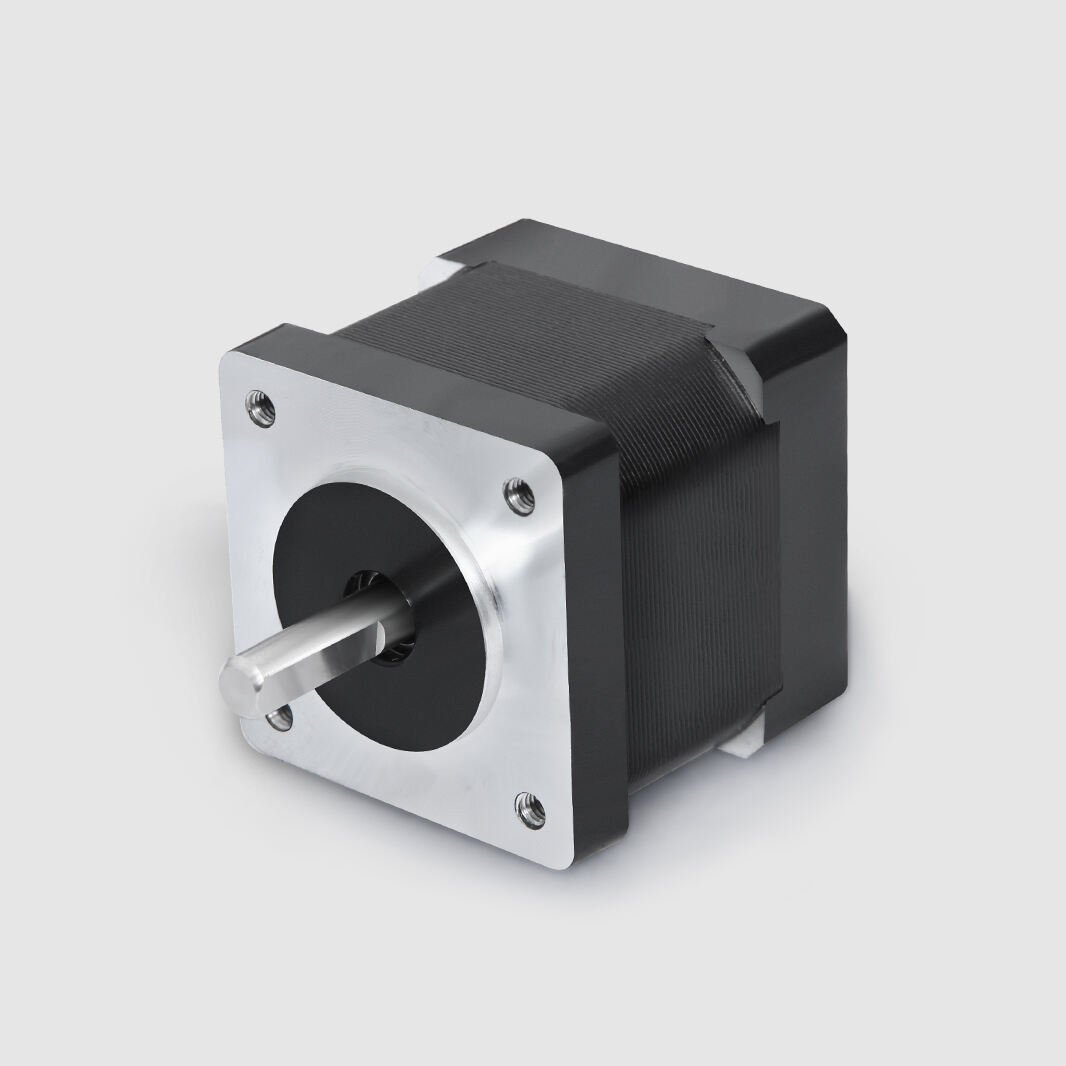

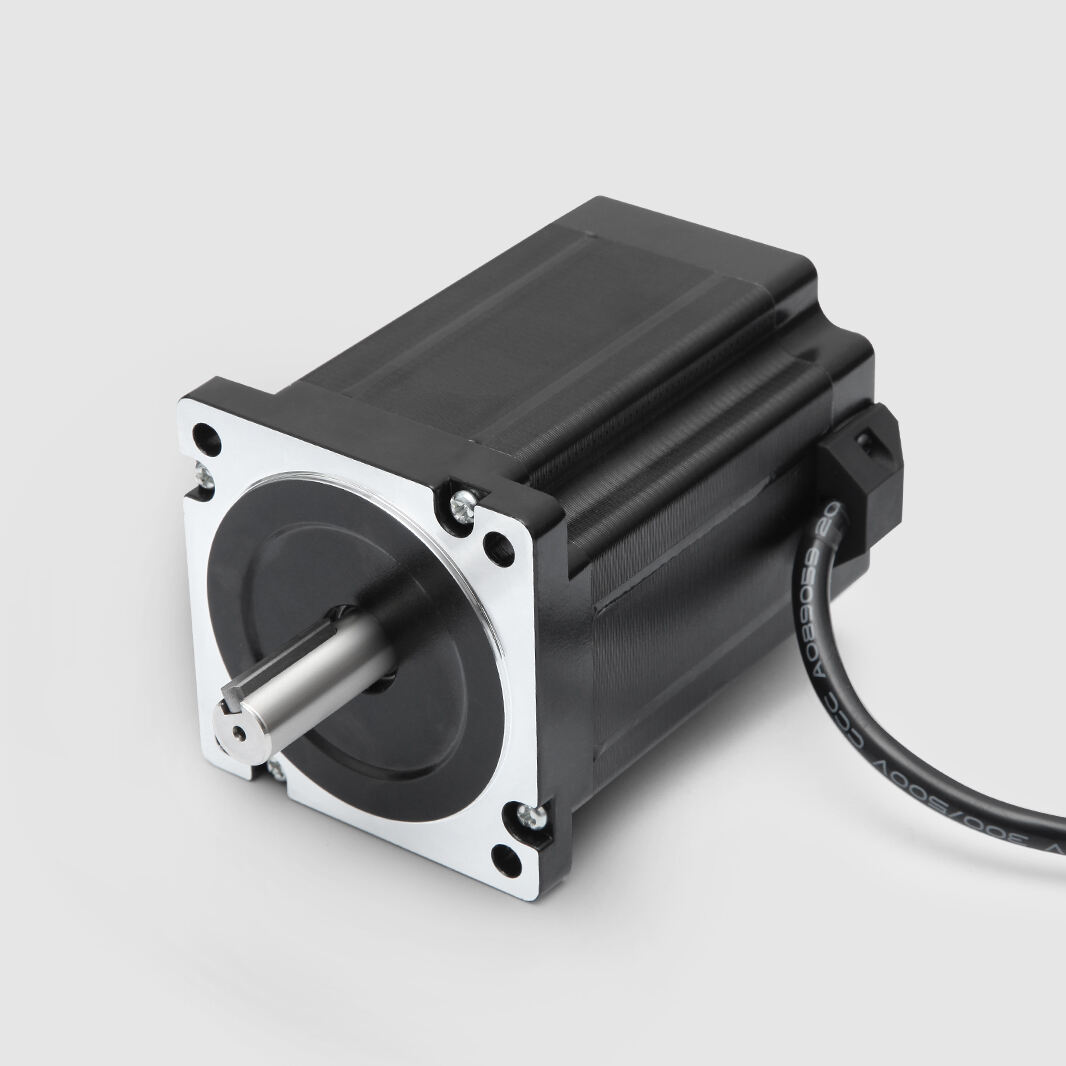

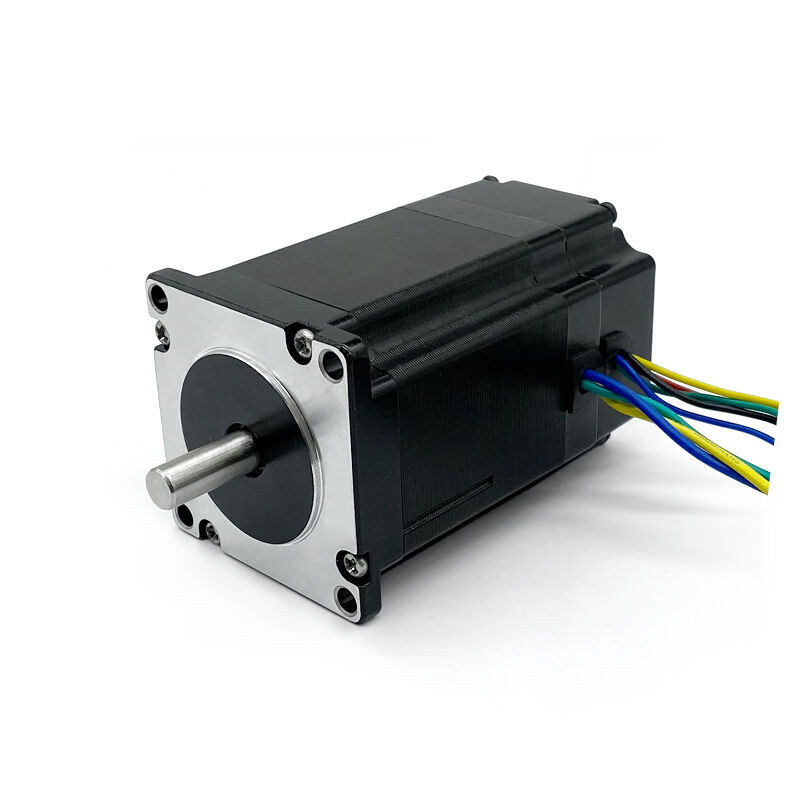

1000w bldc motor

The 1000w BLDC motor represents a cutting-edge solution in modern electric motor technology, combining exceptional performance with energy efficiency. This brushless direct current motor operates at 1000 watts of power output, making it suitable for demanding applications that require reliable and consistent performance. Unlike traditional brushed motors, the 1000w BLDC motor eliminates physical brushes, resulting in reduced friction, lower maintenance requirements, and extended operational lifespan. The motor utilizes electronic commutation through sophisticated control circuits that precisely manage the timing and sequence of current flow to the motor windings. This advanced control system enables the 1000w BLDC motor to deliver superior torque characteristics, variable speed control, and exceptional efficiency ratings often exceeding 90 percent. The motor's construction features permanent magnets in the rotor assembly and electromagnetic windings in the stator, creating a robust and durable design that withstands harsh operating conditions. Key technological features include integrated hall sensors for position feedback, thermal protection systems, and compatibility with various control interfaces including PWM signals and digital communication protocols. The 1000w BLDC motor finds extensive applications across multiple industries, including electric vehicles, industrial automation systems, HVAC equipment, medical devices, robotics, and renewable energy systems. In electric bicycles and scooters, this motor provides smooth acceleration and hill-climbing capability while maintaining battery efficiency. Industrial applications benefit from the motor's precise speed control and high torque output for conveyor systems, pumps, and manufacturing equipment. The motor's quiet operation makes it ideal for residential applications such as ceiling fans and home appliances. Marine applications utilize the 1000w BLDC motor for electric propulsion systems due to its corrosion resistance and reliability in marine environments.