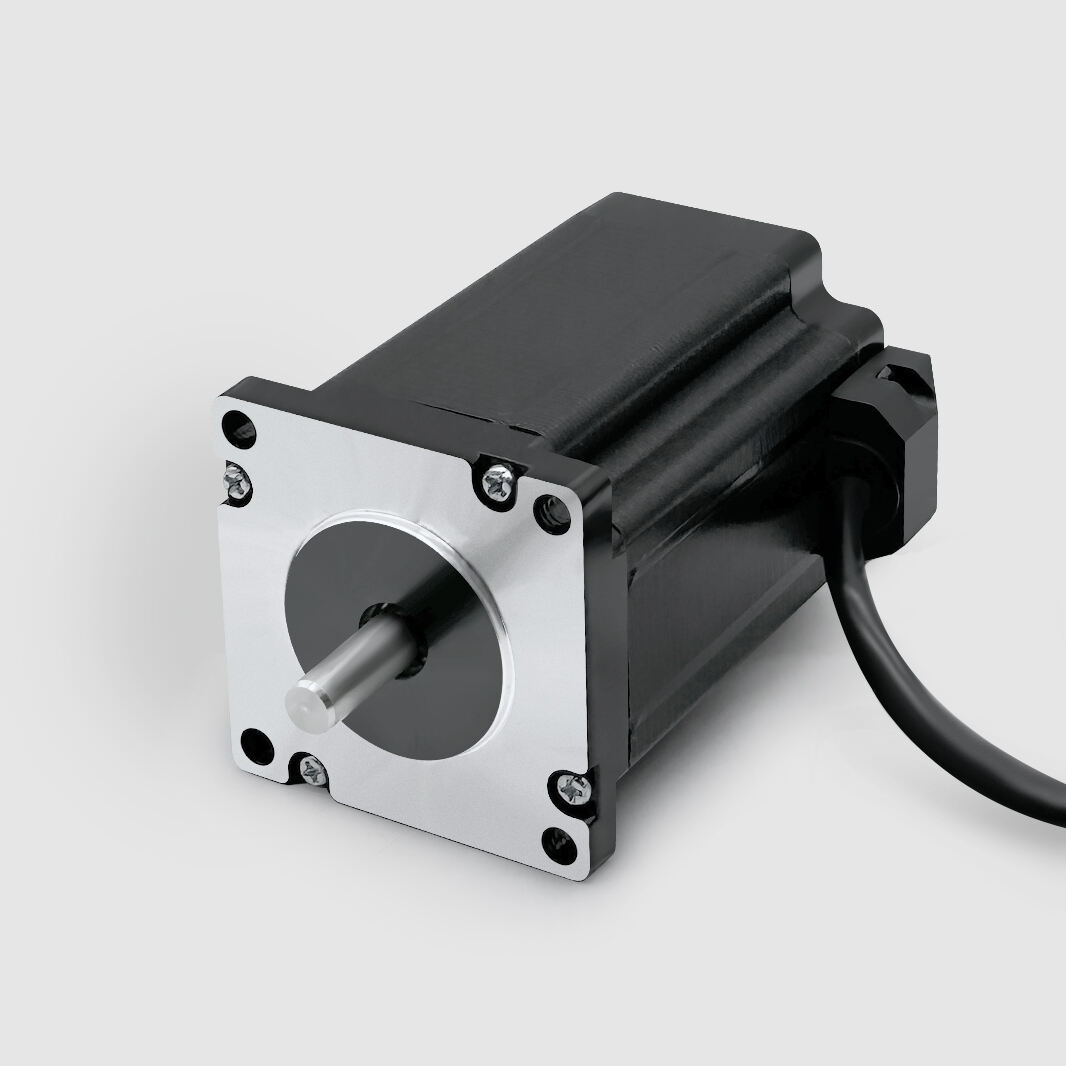

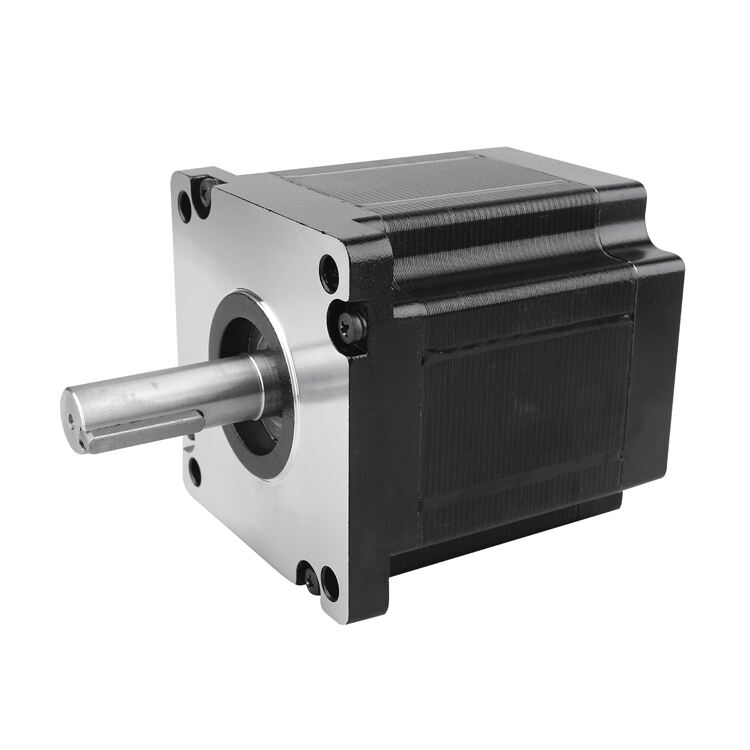

bldc spindle motor

The BLDC spindle motor represents a revolutionary advancement in precision motor technology, combining brushless DC motor principles with high-speed spindle capabilities to deliver exceptional performance across diverse industrial applications. This sophisticated motor system eliminates the traditional carbon brush mechanism found in conventional motors, instead utilizing electronic commutation through advanced control circuits and permanent magnet rotors. The BLDC spindle motor operates on the principle of electromagnetic interaction between stationary windings and rotating permanent magnets, creating smooth, continuous rotation with remarkable precision and efficiency. The main functions of a BLDC spindle motor encompass high-speed rotation for cutting operations, precise positioning for manufacturing processes, and variable speed control for different operational requirements. These motors excel in delivering consistent torque across varying speed ranges while maintaining exceptional rotational accuracy. The technological features that distinguish BLDC spindle motor systems include electronic speed control, regenerative braking capabilities, and intelligent feedback systems that monitor performance parameters in real-time. Advanced sensor integration allows for precise position detection and speed regulation, enabling seamless integration with computer numerical control systems and automated manufacturing equipment. The motor construction incorporates high-grade permanent magnets, precision bearings, and optimized cooling systems to ensure reliable operation under demanding conditions. Applications for BLDC spindle motor technology span numerous industries, from CNC machining centers and woodworking equipment to textile machinery and medical device manufacturing. In metalworking applications, these motors drive cutting tools with exceptional precision, enabling complex machining operations on various materials. The electronics manufacturing sector utilizes BLDC spindle motor systems for PCB drilling, component placement, and quality inspection processes. Additionally, these motors find extensive use in robotic systems, automated assembly lines, and precision measurement equipment where accuracy and reliability are paramount for operational success.