Exceptional Versatility and Application Flexibility

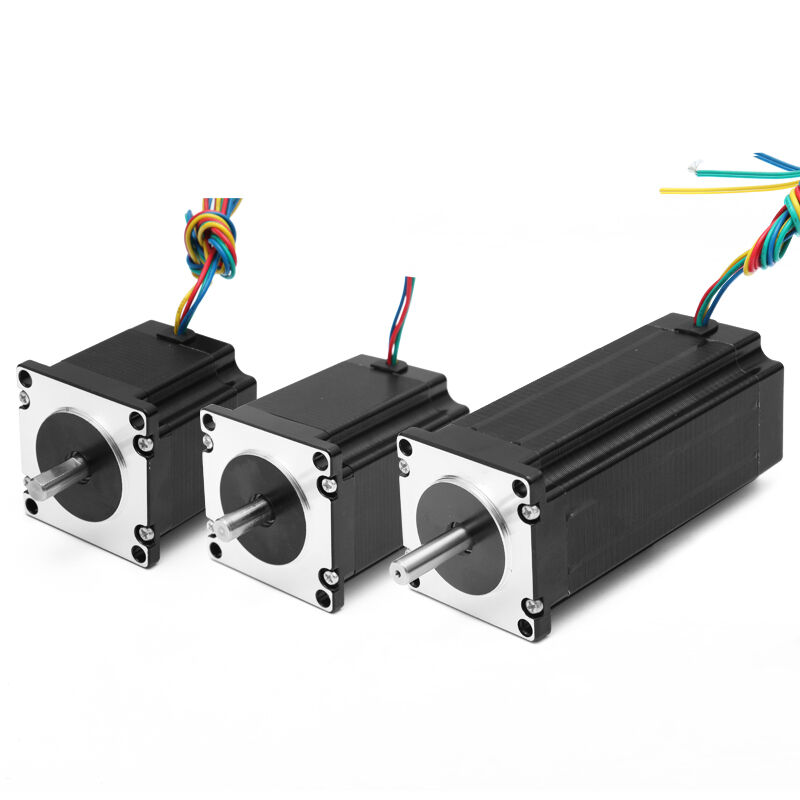

Electric stepping motors demonstrate remarkable versatility that enables their successful deployment across an extraordinarily wide range of applications, from precision laboratory instruments to heavy-duty industrial automation systems. This adaptability stems from the diverse range of sizes, torque ratings, and performance characteristics available in modern electric stepping motor designs, allowing engineers to select optimal solutions for virtually any motion control requirement. Electric stepping motors accommodate various control methods, from simple pulse-and-direction interfaces suitable for basic applications to sophisticated motion controllers that enable complex multi-axis coordination for advanced automation systems. The scalability of electric stepping motors ranges from miniature models suitable for medical devices and consumer electronics to large frame sizes capable of driving substantial industrial loads, ensuring appropriate solutions for applications across all size ranges. Electric stepping motors support multiple operational modes, including full-step operation for maximum torque, half-step mode for improved smoothness, and microstepping techniques that provide ultra-fine positioning resolution for critical applications. This operational flexibility allows system designers to optimize performance characteristics for specific requirements without changing hardware components. The voltage compatibility of electric stepping motors spans from low-voltage battery-operated systems to high-voltage industrial installations, making them suitable for portable equipment, automotive applications, and fixed industrial machinery. Electric stepping motors integrate seamlessly with various feedback systems when applications require closed-loop operation, combining the inherent benefits of step motor technology with the enhanced accuracy of encoder feedback. The thermal operating range of electric stepping motors accommodates both indoor climate-controlled environments and outdoor installations subject to extreme temperature variations, expanding their application potential significantly. Electric stepping motors support both unidirectional and bidirectional operation with equal performance characteristics, making them ideal for applications requiring frequent direction changes such as pick-and-place systems, scanning mechanisms, and oscillating drives. The rapid acceleration and deceleration capabilities of electric stepping motors enable their use in high-speed applications while maintaining precise positioning accuracy, bridging the performance gap between servo systems and traditional step motors. Modern electric stepping motors incorporate advanced magnetic materials and optimized winding configurations that improve efficiency and reduce heat generation, making them suitable for continuous duty applications previously dominated by other motor technologies.