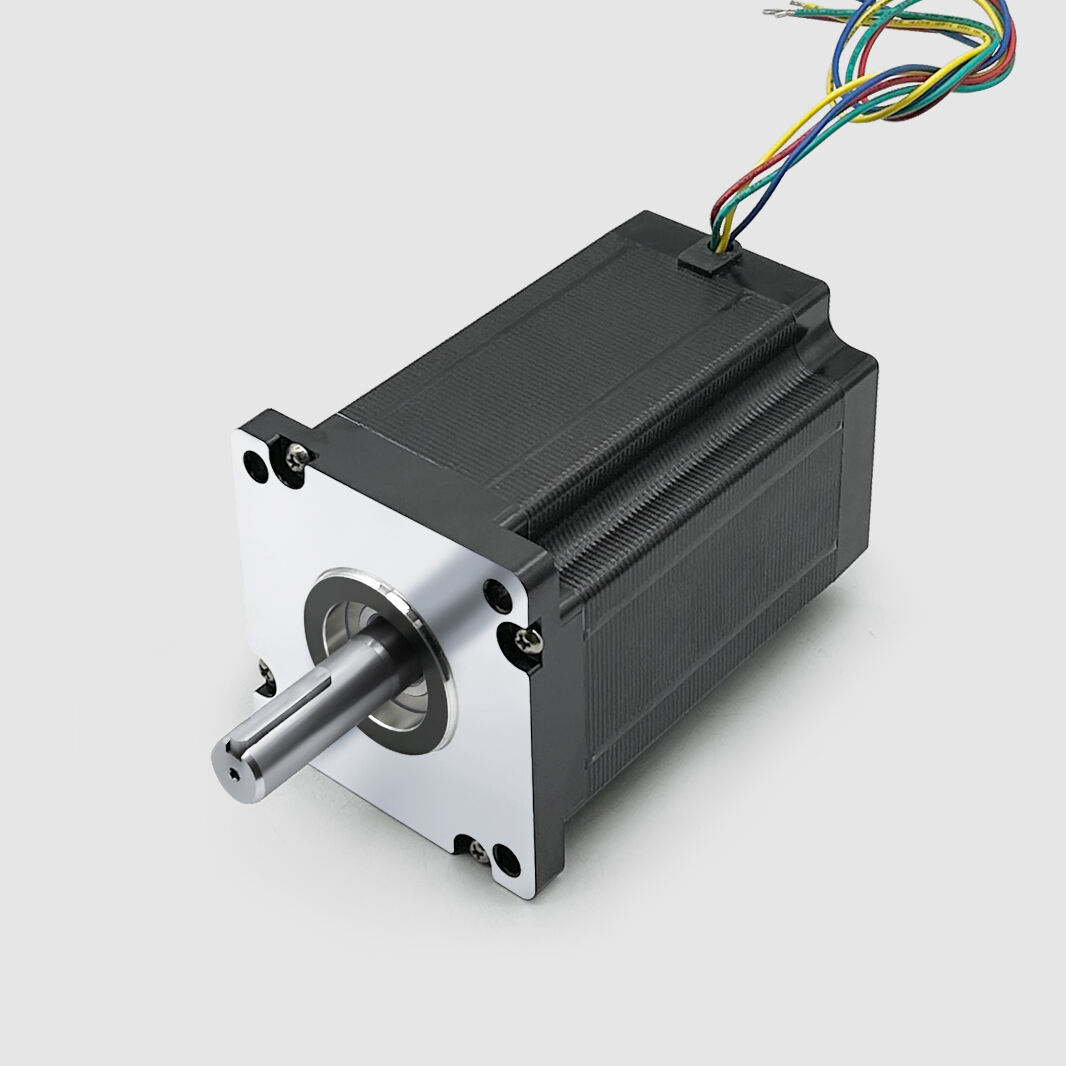

closed loop stepper motor controller

A closed loop stepper motor controller represents a sophisticated advancement in precision motion control technology that combines the simplicity of stepper motors with the accuracy of feedback systems. Unlike traditional open loop stepper motor systems that operate without positional feedback, a closed loop stepper motor controller continuously monitors the actual position of the motor shaft through integrated encoders or other feedback devices. This real-time monitoring capability allows the controller to detect and correct any positioning errors instantly, ensuring exceptional accuracy and reliability in demanding applications. The closed loop stepper motor controller incorporates advanced algorithms that compare the commanded position with the actual position, making automatic adjustments to compensate for any deviations. This feedback mechanism eliminates the common issues associated with traditional stepper systems, such as step loss, resonance problems, and reduced torque at high speeds. The main functions of a closed loop stepper motor controller include precise position control, velocity regulation, torque optimization, and error detection. These controllers feature sophisticated microprocessor-based control circuits that process encoder feedback signals and execute complex motion profiles with remarkable precision. The technological features encompass high-resolution position feedback, adaptive current control, anti-resonance algorithms, and comprehensive fault detection systems. Applications for closed loop stepper motor controllers span across numerous industries including manufacturing automation, robotics, CNC machinery, medical devices, semiconductor equipment, and packaging systems. In manufacturing environments, these controllers enable precise positioning for assembly operations, quality inspection systems, and material handling equipment. The pharmaceutical and medical device industries rely on closed loop stepper motor controllers for accurate dosing systems, surgical equipment, and diagnostic machinery where precision is critical for patient safety. The versatility and reliability of closed loop stepper motor controllers make them ideal solutions for applications requiring both high accuracy and robust performance in challenging industrial environments.